Introduction of Benson Boiler

The Benson boiler was introduced by Mark Benson in 1922. Benson boiler is a high-pressure and a forced circulation water tube boiler. The best thing about this boiler is the absence of the steam separating drum.

The whole process of heating stem formation and superheating is done in a single continuous tube. But sometimes to improve efficiency, parallel circuits can be used.

Generating capacity:- 150tons/hr

Working pressure:- 220 bar

Obtained temperature:- 540 degrees Celsius

Efficiency of boiler:- As high as 90%

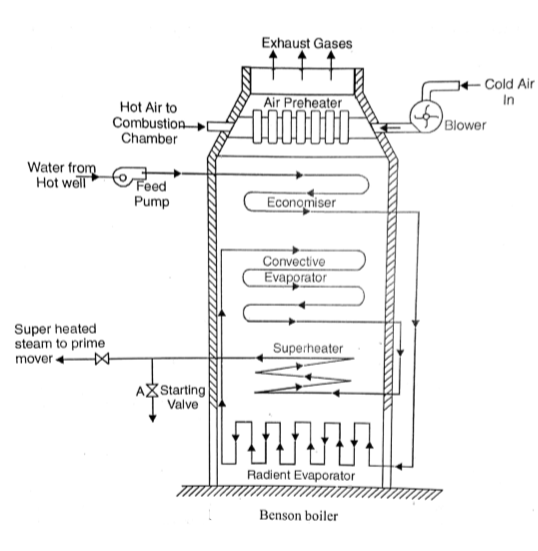

Construction Details of Benson Boiler

Air preheater:- Air preheater is a device in which air is preheated for economical combustion.

Economizer:- In economizer, the sensible heat is added to feed water.

Radiative surface:– This surface of tubes where most of the heat is transmitted and water gets heated almost to the critical temperature.

Evaporative surface:– Evaporative surface, where evaporation of the water is being completed and superheating begins.

Super-heater:– Super-heater in which steam is super heated and used for work.

Working of Benson Boiler

The water is passed through the economizer into the radiant evaporator. In a radiant evaporator maximum amount of water is converted into steam. The remaining water is evaporated in a convective evaporator where the heat of hot gases is utilized by Convection.

Now, this steam is finally passed through the superheater and takeoff by a valve (B) and used to run the prime movers. During starting, the water is passed through the economizer, radiant evaporator, Convective evaporator, superheater, and back to the feed line which starts from valve A.

During this starting, valve (B) is closed. Now, the steam generation starts and it becomes superheated, so, valve (A) is closed and valve (B) is opened. The precaution is taken that the circulating pump is started first then start burners to avoid the overheating of evaporator and superheater tubes.

Advantages of Benson Boiler

- There are no pressure limitations and supercritical pressures can be employed.

- A drum is absent so the cost of the drum is eliminated.

- The boiler is a self-contained unit and can be readily located outdoors.

- Evaporation is quick.

- Benson boiler is lighter in weight, higher specific output with a higher factor of safety.

- Absent of circulating pump and down-comers.

Disadvantages of Benson Boiler

- The major difficulty is salt formation in the transformation zone (evaporator) when all the remaining water is converted into steam.

- Removing of deposits salt is required after each 4000 working hours by special means.

- Since storage capacity is the only tube and hence requires close coordination between steam, feedwater, and fuel input.

- On evaporative tubes, there is a chance of corrosion.