LaMont boiler is a modern high pressure, forced circulation water tube boiler that was introduced by Walter Douglas LaMont in 1925 and is mainly used in the USA and Europe.

Principle:-

It works on the principle of forced circulation of water. The circulation of water and steam mixture occurs by an external pump that supplies water at a higher pressure than in a natural circulation boiler.

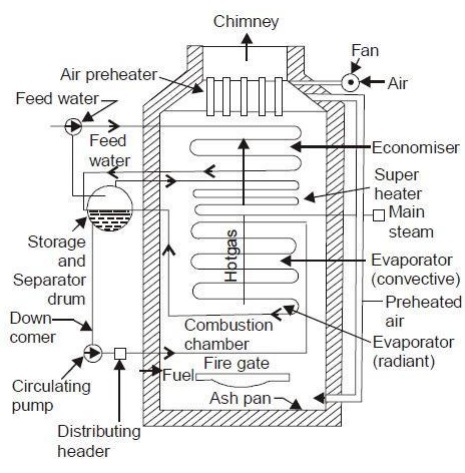

A LaMont Boiler consists of parts like:-

- Feed pump

- Economizer

- Centrifugal Pump

- Evaporator

- Grate

- Furnace

- Super-heater

- Water Steam Separator

- Air Preheater

- Radiant evaporator

- Convective evaporator

Feed Pump:-

The feed water is being supplied by the feed pump into the boiler from the hot well.

Economizer:-

It is a device that is used to increase the efficiency of the boiler. The main use of an economizer is to preheat the water by using the remaining heat of the combustion gases.

Centrifugal Pump:-

The water is being circulated by a centrifugal pump in a boiler.

Evaporator:-

The main function of the evaporator is to evaporate water into steam. This also cools down the furnace wall.

Grate:-

The grate is placed at the bottom of the boiler where the fuel is burned.

Furnace:-

The vertical furnace is used to burn the fuel in the Lamont boiler.

Superheater:-

The superheater is used to superheat the saturated steam coming from the evaporator.

Water steam separator:-

It separates the stem from the mixture of water – stem coming from the evaporator and send it to the superheater.

Air Preheater:-

Its main function is to preheat the air before entering the furnace.

Radiant evaporator:-

The main function of the radiant evaporator is to evaporate the water steam mixtures with the help of radiation.

Convective evaporator:-

The main work of a convective evaporator is to change the mixture of steam and water into saturated steam by heat transfer.

Working of LaMont Boiler:-

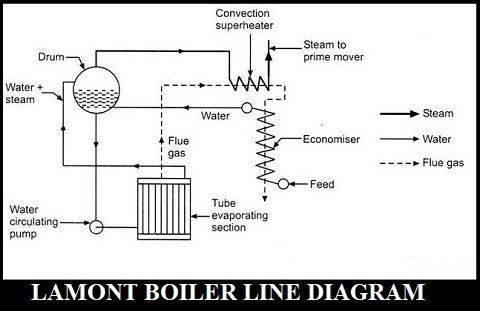

The feedwater is pumped by the feed pump from the hot well through the economizer and preheated water is supplied to the boiler drum. The water is heated up by the hot gases flowing in the upward direction which are later exhausted through the chimney high in the atmosphere to reduce air pollution.

This boiler drum also acts as a steam separating drum. The circulating pump pumps the water to the distributor’s head. The boiler generates 40 to 50 tonnes of superheated steam per hour at 500 de degrees Celsius.

This distributor header has nozzles, which distribute the feed water into the radiant evaporator. Now, the Radiant evaporator heats the water and changes it into steam. So, Form the radiant evaporator the water-steam mixture passes through the convective evaporator.

Here the temperature of the fluid increase and most of the water gets converted into saturated steam. The saturated steam enters into the steam separator drum. The steam separator drum separates the steam from water. From the steam separator drum, steam passes through the superheater.

The superheater increases the temperature of the steam to the desired level. And lastly, the superheated steam is being transferred to the steam collecting drum or made to strike on the blades of the turbine.

Advantages of LaMont boiler:-

- LaMont boiler can generate a high amount of steam.

- It is easy to start its operation.

- The construction design of the Lamont boiler is very simple and easy to understand.

- This boiler can reassemble with the natural circulation boiler and it has a high heat transfer rate.

Disadvantages of LaMont Boiler:-

There is a bubble formation at the surfaces of the tubes in this boiler. This reduces the heat transfer rate to the steamFor this reason a little problem with the total amount of steam generation.