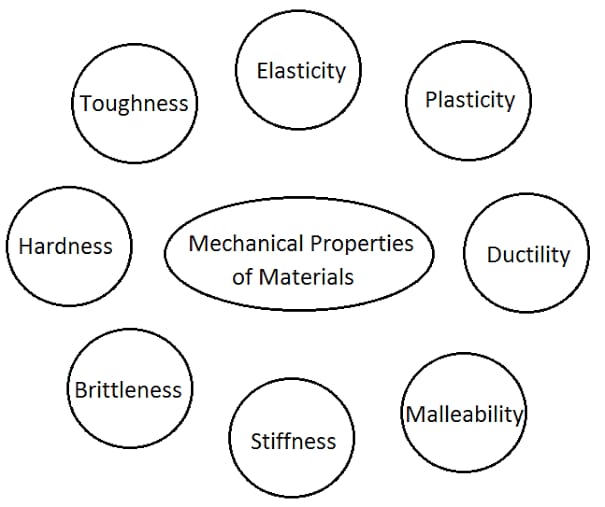

Elasticity

Elasticity may be defined as property by virtue of which the material regains its original shape and size when the deforming force is removed.

Elastic Limit

When the deforming force is applied on a substance it regains its original configuration but after a certain limit of deforming force, the elastic bodies are unable to regain complete original configuration which is known as elastic limit.

Plasticity

Plasticity is just opposite to elasticity. The object never regains its original shape when the deforming force is removed.

Toughness

It is the ability of a material to absorb energy during plastic deformation up to fracture. Toughness of a material then is indicated by the total area under the material’s tensile stress-strain curve up to the point of fracture.

Resilience

Resilience is somehow related to toughnesss. It is the ability of a material to absorb energy when it is deformed elastically and release that energy when the deforming force is removed.

Proof Resilience

Proof Resilience is defined as the maximum energy that can be absorbed up to the elastic limit, without creating a permanent distortion.

Modulus of Resilience

It may be defined as the strain energy per unit volume required to stress a material from a state when no deforming force is applied upto the point of yielding.

Ductility

In simple words, we can define ductility as a ability of a material to be drawn from a large section to a small section such as in wire drawing. Ductility is referred to as a capacity of a material to undergo deformation under tension without rupture. We can express ductility as percent elongation or percent area reduction from a tensile test.

Ductility is a measure of the degree of plastic deformation that has been sustained at fracture, A material that experiences very little or no plastic deformation upon the fracture is termed as Brittle.

Malleability

Malleability can be defined as the capacity of a material to withstand deformation under compression without rupture. For example forging and rolling operations. The ability of a metal to be formed by hammering or rolling is called malleability. For example lead, gold is most malleable. Malleability differs from ductility in the sense that ductility is considered a tensile property and malleability a compressive property.

Brittleness

Brittleness is defined as a tendency to fracture without appreciable deformation and is therefore the opposite of ductility or malleability. A brittle material will fracture with little permanent deformation or distortion; it is a sudden failure. A brittle material is hard and has little ductility.

Hardness

The property of material which resist the penetration. It is defined as the ability of material which resist scratching, cutting , abration, penetration, wear and tear. The hardness is ability to cut another material. Test such as Brinell, Rockwell, vickers etc. are generally used to measure hardness. The hardness of metals is also increased by alloying cold work and precipitation hardening.

Strength

It is the ability of material to withstand the external force without distraction or breaking. The strength of material varies according to the type of loading that is tensile strength, compressive strength and shear strength.

Elastic After Effect

The delay in regaining the original configuration by an elastic body after the removal of a deforming force is called elastic after effect. The elastic after effect is negligibly small for quartz and phosphor bronze, but very large for glass fiber.

Elastic Fatigue

It is the property of an elastic body by virtue of which its behaviour becomes less elastic under the the action of repeated alternating deforming forces.

Creep

Creep is the time dependent continued plastic deformation at constant