Introduction of Velox Boiler

The Velox boiler is a high-pressure, forced circulation, pressurized combustion boiler, but with the limitations of firing with fluid fuel (oil or gas) under pressure. It was introduced in the 1930s by Brown Boveri Company of Switzerland. Velox boiler was primarily marketed for electricity generation.

They were anticipated to be used in steam locomotives on land as well as on sea but eventually lost to the efficiency and cost-effectiveness of supercharged diesel engines and constant pressure combustion gas turbines. A Velox boiler is mostly used in gas turbines. The generating stem capacity of the Velox boiler is 100tones/hr.

Principle of Heat Transferred

At supersonic gas velocity (when gas velocity exceeds sound velocity) the heat transfer rate from gases is much more than that of sub-sonic gas velocity.

The advantages of this theory are incorporated in the Velox boiler in which larger heat transfer from a small area is achieved.

Working of Velox Boiler

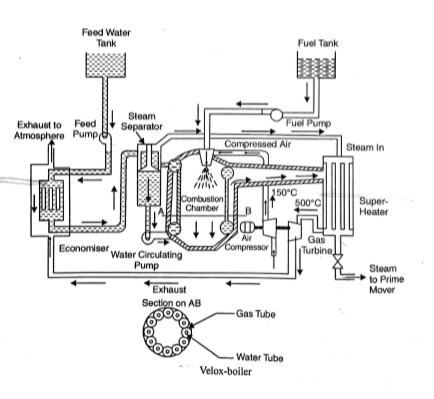

Air is being compressed to 2.5 bar by a compressor which is run by the turbine, before supplying to the combustion chamber. Thus the air in the combustion chamber gets supersonic velocity, this helps in effective heat transfer in the combustion chamber.

Now the heat is being transferred from gases to water while passing through the annulus to generate the steam. Thus a mixture of water and steam which is formed then passes into a separator. Due to centrifugal force the heavier water particles to be thrown outwards on the wall.

This effect separates the steam from water. The separated steam is further passed to the superheater and then used to run the prime mover. The flue gases coming out from the annulus at the top are further passed over the superheater where its heat is used by the superheater.

The gases coming out of the superheater are used to run a gas turbine. The output of this turbine is used to run the air compressor. Finally, the exhaust gases coming out from the gas turbine are passed through the economizer to utilize the remaining heat.

Advantages of Velox Boiler

- Its thermal capacity is about 90 to 95%.

- Very high combustion rate.

- Less excess air is required as pressurized air is used.

- It can be started quickly.

- It is a compact unit and offers higher flexibility.

Disadvantages of Velox boiler

Velox boiler requires additional parts like:-

- Electric starter.

- Gas turbine to drive air compressor.

- Steam turbine for water circulation.

But, in the Velox boiler, there is a limitation for its size.