Gears can be defined as toothed wheels or multi-lobed cams, which transmit power and motion from one shaft to another shaft by means of successive engagement of teeth.

Gear drives offer the following advantages:-

- Gear drive is a positive drive whose velocity ratio remains constant.

- The compact construction of gear drives is because the center distance between the shaft is relatively small.

- Gear drives can transmit very large power, which is beyond the range of belt or chain drives.

- It can transmit motion at a very low velocity, which is not possible with the belt drive.

- The efficiency of gear drives is very high even up to 99% in the case of spur gears.

- A provision can be made in the gearbox for gear shifting, thus changing the velocity ratio for a wide range.

The disadvantages of gear drives:–

- Mostly Gear drives are costly and their maintenance cost is also higher.

- The manufacturing processes of gear are complicated and highly specialized.

- Generally, Gear drives require careful attention for lubrication and cleanliness.

- They also require precise alignment of the shafts

Gears are broadly classified into four groups, viz. spur, helical bevel, and worm gears.

Spur Gear:-

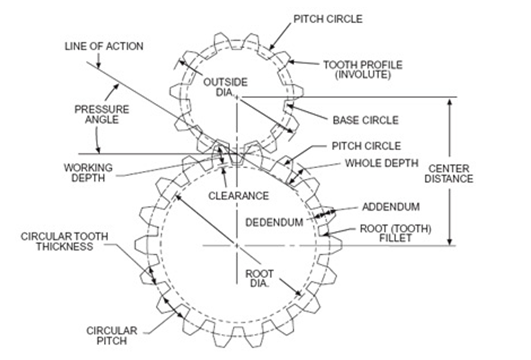

In spur gear, teeth are cut parallel to the axis of the shaft and the teeth are parallel to the axis of the shaft, spur gears are used only when the shafts are parallel. Basically, the profile of the gear tooth is in the shape of an involute curve and it remains identical along the entire width of the gear wheel.

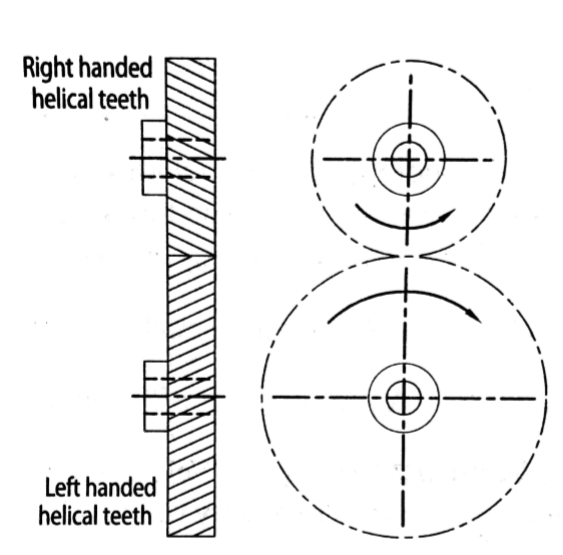

Helical Gear:-

The teeth of helical gears are cut at an angle with the axis of the shaft. The involute profile of helical gear is similar to that of spur Gear. But this involute profile is in a plane, which is perpendicular to the tooth element. So, the magnitude of the helix angle of pinion and gear is the same, however, the hand of the helix is the opposite. In a helical gear, a right-hand pinion meshes with a left-hand gear and vice versa.

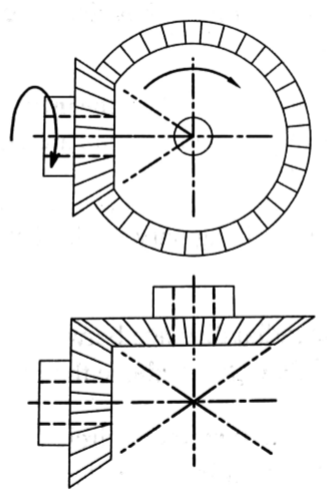

Bevel Gears:-

The shape bevel gear is like a truncated cone. The size of the gear tooth, including the thickness and height, decreases towards the apex of the cone. Bevel gears are normally used for the shafts, which are at right angles to each other. Thus, however, is not a rigid condition and the angle can be slightly more or less than 90 degrees. The teeth of bevel gears can be straight or spiral.

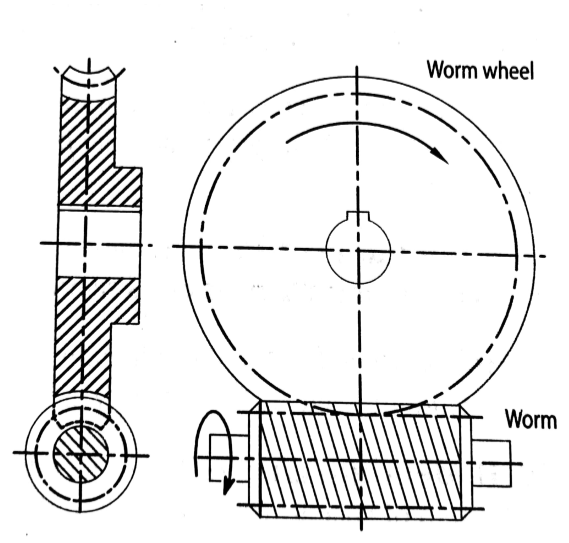

Worm Gears:-

The worn gears consist of a worm and a worm wheel. The worn is in the form of a threaded screw, which meshes with the matching wheel. The threads on the worm can be single or multi-start and usually have a small lead. As we know the worm gear drives are used for shafts, the axes of which do not intersect and are perpendicular to each other. The worm imposes a high thrust load, while the worm wheel imposes a high radial load on the shafts. Worm gear drives are characterized by high-speed reduction.