Introduction of Lancashire Boiler

Lancashire boiler is a stationary, fire tube, internally fired, natural circulation horizontal boiler.

It is widely used due to its ability to burn coal of inferior quality and for better steaming quality. Working pressure range up to 20 atm. and capacity up to 9000 kg/hr.

Construction of Lancashire Boiler

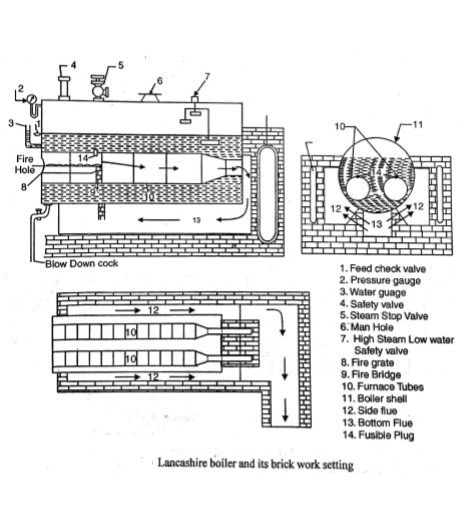

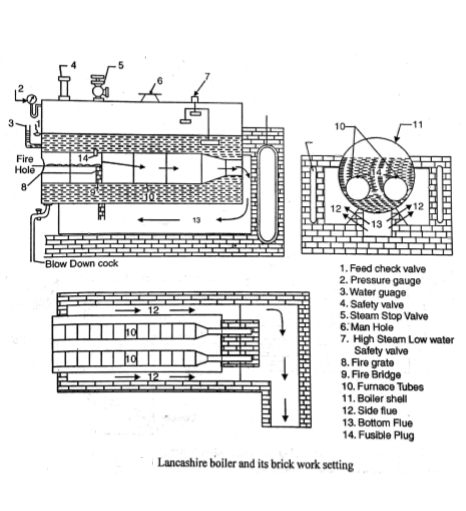

The Lancashire boiler has a cylindrical shell of 2 m in diameter and 8 to 10 m in length. The external part of Shell is formed by brickwork and acts as a heating surface. The Lancashire boiler consists of a cylindrical shell and two big furnace tubes pass right through this one bottom flue and two side flues are formed by the brick setting.

The grates are provided at the front of the main flue tubes. Now, the coal is being fed through the fire door to the grate. The damper is provided to control the flow of gases. The blow-off cock is also provided beneath the front portion of the boiler shell for cleaning sediment deposits. A fusible plug is mounted on the top just over the grate.

Working of Lancashire Boiler

The flue gases formed by the combustion of fuel move along the main flue or furnace tube. They are deflected up with a brick wall bridge. After passing through the main flue they deflect down and goes through the bottom flue.

These gases heat the lower part of the shell.

After traveling back and front, these gases divide in two distinct paths in the side flues and heat the side of the water shell. The economizer is placed at the end of side flues before exhausting the hot gases to the chimney.

The feedwater before a feed to the boiler is passed through the economizer. The feed water extracts the heat from exhaust gases and increases its temperature. This leads to improving efficiency.

Advantages of Lancashire Boiler

- Maintenance is easy.

- The heating surface area per unit volume of the boiler is large.

- Load fluctuation can be meet easily due to its large reserve capacity.

- Superheater and economizer improve its overall efficiency up to 80-85%.

Disadvantages of Lancashire Boiler

- High-pressure steam is not produced, because this is a low-pressure type boiler.

- It has a limited grate area due to the small diameter of the flue tubes.

- The steam production rate is low. It is about 9000 kg/hr.

- Corrosion occurs in the water legs.

- This boiler requires more floor space.

- This boiler has a leakage problem.

- It requires more time to generate steam.

- It cannot generate high-pressure steam if required.

- Grates are situated at the inlet of the fire tube, which has a small diameter.