Introduction of Cochran Boiler

The Cochran boiler is a vertical, multitube boiler used for small capacity steam generation. It is available in different sizes of evaporative capacity ranging from 150 to 3000 kg/hr and working pressure up to 20 bar.

Construction of Cochran boiler

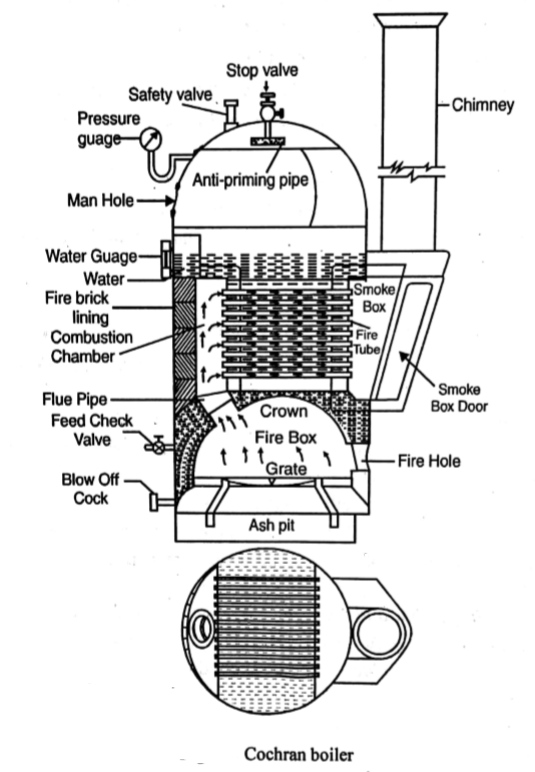

The Cochran boiler consists of a cylindrical shell having a hemispherical crown. The furnace is also of hemispherical shape. The firegrate is placed at the bottom of the furnace. The Ash pit is provided below the fire gate. The coal is fed through the fire door into the grate.

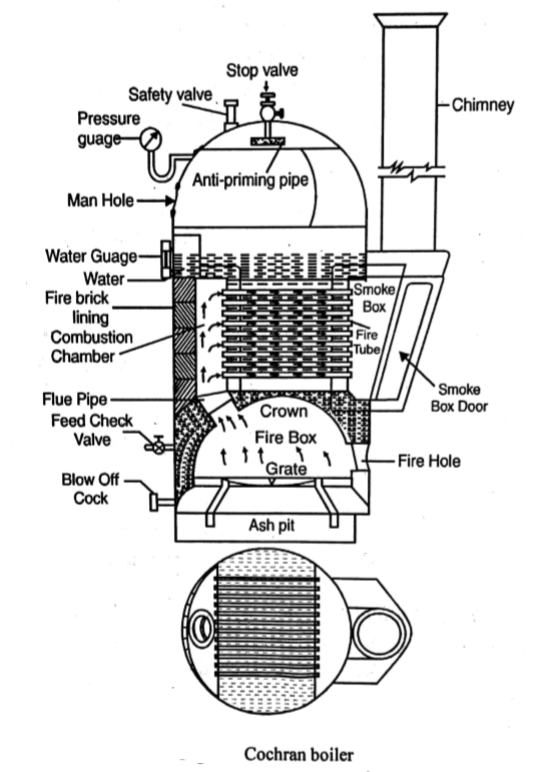

The Ash formed is collected in the Ash pit and then manually removed from time to time. The furnace and combustion chamber are connected by a pipe. The back portion of the combustion chamber is lined with refractory bricks. Horizontal fire tubes are provided generally of 5-6 cm diameter and 150-180 in numbers.

A manhole is provided near the crown of the shell for the man to go inside and cleaning under non-working conditions. Also, some hand holes are provided around the outer shell for cleaning of boiler. The smokebox is provided with the door for the cleaning of fire tubes.

Working of Cochran boiler

The fuel is burnt on the grate and hot gases go upward through the flue pipe and reach the combustion chamber. In the combustion chamber, the flue gases pass through the fire tubes, and from the fire tube, it goes to the smokebox and finally discharged to the atmosphere through the chimney.

During the travel, flue gases transfer their heat to the water surrounding fire tubes, and then later converted to steam. Necessary water is feed inside the boiler from the top of the shell by the cooler wall.

Advantages of Cochran Boiler

- Very compact and requires minimum floor area.

- Any quality of fuel can be used in the Cochran boiler.

- Best for small capacity requirements.

- Thermal efficiency is about 70-75%.

Disadvantages of Cochran Boiler

- Low steam generation rate.

- Limited pressure handles capacity.

- It is difficult to inspect and maintain

Required Mountings for Cochran Boiler

- Pressure gauge:- This indicates the pressure of steam in the boiler.

- Water level indicator:- This indicates the water level in the boiler.

- Safety valve:- This prevents the increase of steam pressure in the boiler above its design pressure.

- Fusible plug:- When the temperature of the shell increases above a particular level, the fusible plug melts and forms an opening hole, water through this hole pushes on the grate, and combustion is fired off.

- Blow off cock:- Deposited salt is removed with the help of this cock. It is situated at the bottom of the Cochran boiler.

- Steam stop valve:- It regulates the flow of steam supply outside.

- Feed check valve:- High-pressure feed water is supplied to the boiler through this valve. It also prevents the backflow of steam through the valve.