HELICAL SPRING: BASIC TERMS AND NOTATIONS

Helical Spring ,either Compression or Extension , shows a lot of applications in Mechanical ENGINEERING.

Before knowing the stresses and deflections in Helical Spring, its important to know basic terms and notations used for Helical Spring.

TERMINOLOGY:

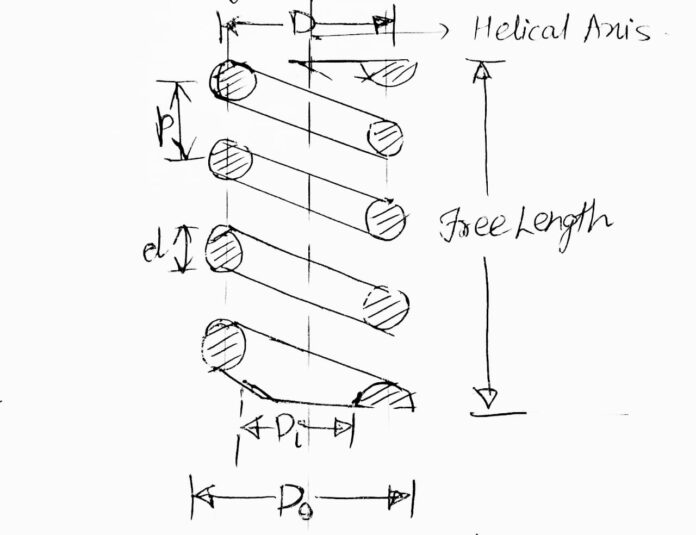

A basic Helical Compression Spring (HCS) diagram is shown below :

NOTATIONS:

p= Pitch of the Spring Coil

d= Wire Diame2ter

D= Mean Coil Diameter

Di= Inside Coil Diameter

Do= Outside Coil Diameter

** Mean Coil Diameter = Average of Inside Coil Diameter(Di) and Outside Coil Diameter(Do).

D= (Do+ Di)/2

** An important parameter used in design of springs developed to be Spring Index (C).

Spring Index (C) =(Mean Coil Diameter)/(Wire Diameter)

C = D/d

SIGNIFICANCE OF C :

C (SPRING INDEX) represents the relative sharpness of the Curvature of the coil.

RANGES OF C :

1) C<3 : High curvature sharpness. Due to this, stress concentration occurs.These springs very difficult to make , and also special care taken in order to avoid spring failure.

2) C>15: Coil Diameter observes large variation in values. These springs become more prone to Buckling(sudden change in shape) and also has risk of Tangling(mixing up weirdly).

3) 4<C<12 : Optimum range of C for spring manufacturing process.

4) 6<C<9: Optimum range of C for spring manufacturing process for close tolerance springs and for cyclic loading induced springs.

TERMS RELATED TO LENGTH OF SPRING :

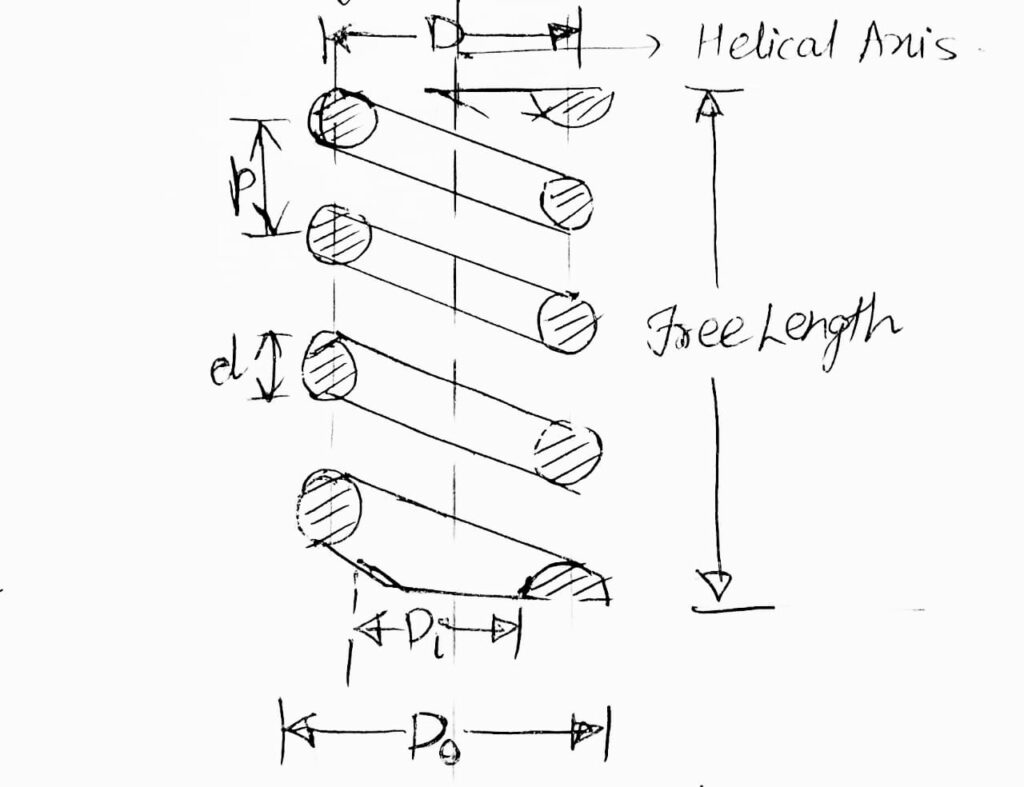

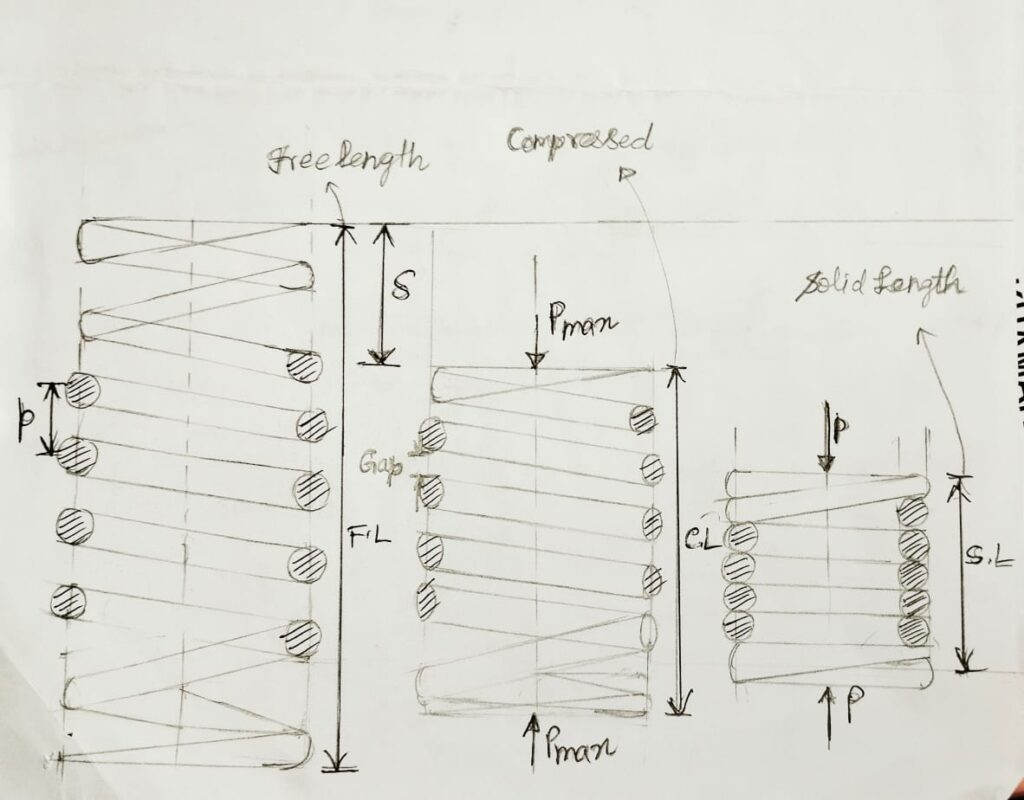

There are actually three lengths of a spring that occur at various conditions which are as follows:

1) FREE LENGTH: Defined as the Axial Length of the H.C.S in unloaded condition.

Here, no external force acts on the spring.

Also defined as length of spring in free condition before being set to application.

FREE LENGTH=Compressed length+ δ = Solid length+Total axial gap +δ

2) SOLID LENGTH: Defined as the Axial Length of the H.C.S in compressed condition ; such that the adjacent coils touch each other.

It is Max. Compression point(i.e spring cannot be compressed after this point).

SOLID LENGTH= Nt.d Where; Nt= Total no.of turns

3) COMPRESSED LENGTH: Defined as the Axial Length of the H.C.S in that condition, when the Maximum Compressive force occurs.

Here, Spring experiences Maximum Deflection (δ) . A special clearance/ gap kept between the coils during this condition.

This is mainly done in order to avoid clashing of two adjacent or coincident coils.

Clashing Allowance/Total Gap = 15 % of (δ). Mostly, Assumed gap is 1-2 mm.

Mathematical expression: TOTAL GAP = (Nt-1) * Gap b/w adjacent coils

OTHER TERMS AND NOTATIONS:

1) PITCH : Axial distance b/w adjacent coils in uncompressed state of spring. Denoted by P.

P= (Free length)/ (Nt-1)

2) STIFFNESS : Force required to produce Unit Deflection. Denoted by k.

k = P/δ

3) ACTIVE AND INACTIVE COILS:

a) ACTIVE COILS : These coils in the spring mainly contribute to the spring action as well as support external force and deflect under load action.

b) INACTIVE COILS : These coils in the spring doesn’t contribute to the spring action and other motion features.

If N= No. of active coils

Nt= total no. of coils

Inactive Coils = Nt-N