Keys are a machine element, which is used to connect the transmission shaft to rotating machine elements.

For example- Pulley, Gears, sprocket, or flywheel.

The two basic functions of the key are as follows:-

1) The key is to transmit the torque from the shaft to the hub of the mating element and vice-versa.

2) The key is to prevent relative rotational motion between the shaft and the joined machine element.

A slot machine on the shaft that accommodates the key is called the keyway. The main drawback of the keyway is stress concentration in the shaft and the part becomes weak. Keys are made up of plain Carbon Steel in order to withstand shear and compressive stresses resulting from the transmission of torque.

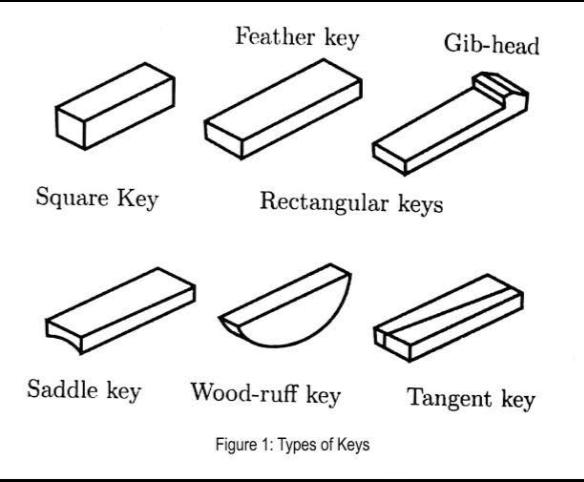

There are different ways to classify the keys:-

1)Sandal key and Sunk key

2)Square key and Flat key

3)Taper key and parallel key

4)Key with and without gib head.

Saddle Key:-

The saddle key fits in the keyway of the hub only. there is no keyway on the shaft. There are two types of saddle key, hollow and Flat. A flat sandal key has a flat surface at the bottom and it sits on the flat surface machined on the shaft. The power is transmitted by the means of friction.

Advantages of saddle key:-

Saddle keys are used for light-duty and low power transmission as compared with sunk keys.

The cost of the saddle key joint is less than that of the Sanki joint.

Disadvantages of saddle key:–

It has a low Power transmitting capacity.

It can’t be used in heavy-duty applications.

Sunk Key:-

The sunk key is the key that fits into the keyway on the shaft and the remaining half in the keyway on the hub. The keyways are required both on the shaft as well as on the hub of the mating element. The power is transmitted due to the shear resistance of the key in the sunk key.

The relative motion between the shaft and the hub can be, prevented by the shear resistance of the key. The sunk key with a square or rectangular cross-section is widely used. Now, a sunk key with a rectangular cross-section is also called a flat key. Basically, the flag key has more stability as compared with a square key.

That’s why square keys are used in general industrial machinery. Flat keys are most suitable for machine tool applications, where additional stability of the connection is desirable.

Advantage of the sunk key:-

The sunk key is for heavy-duty applications only.

The disadvantage of sunk key:–

The cost of the sunk key joint is more than that of the saddle key joint