NOTCH : SIGNIFICANCE AND EFFECT ON DESIGN

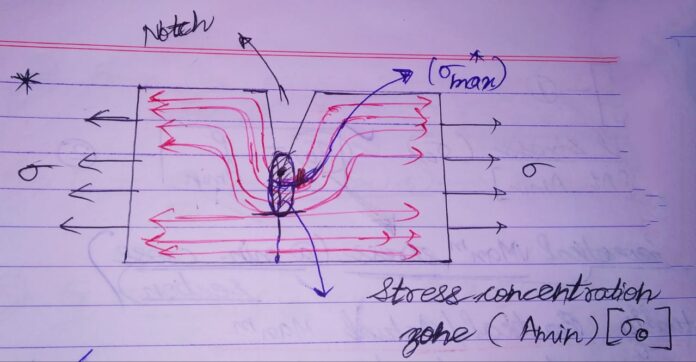

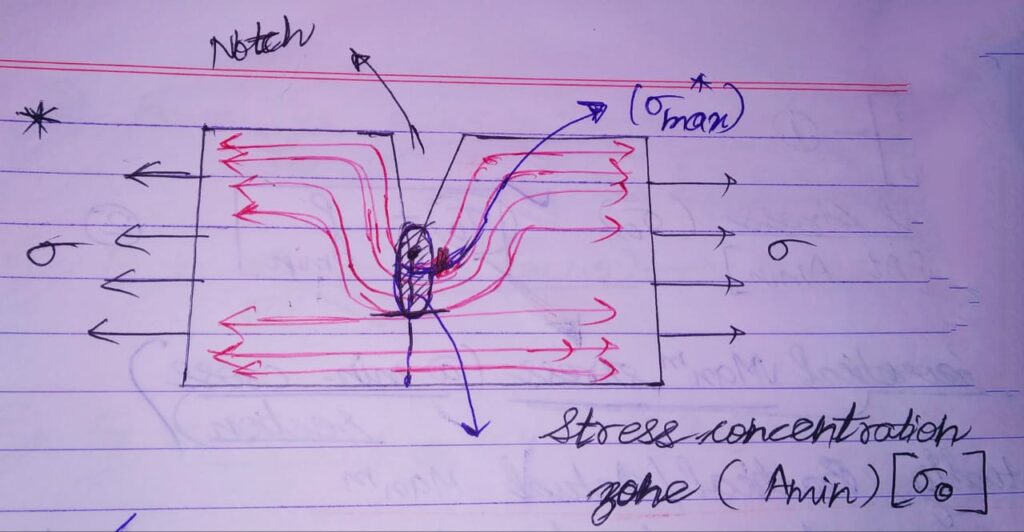

NOTCH : Defined as a purposely introduced defect (usually U-shaped or V-shaped or circular shaped) on a planar machine component.

Therefore, it causes stress concentration on its own region.

Due to this, presence of Notch plays an important role in designing components in conditions of fluctuating/ fatigue loading.

STRESS CONCENTRATION IN FATIGUE LOADING – PRACTICAL STUDY AND OBSERVATION ANALYSIS

OBSERVATION: The actual reduction in endurance limit due to stress concentration came out to be less than the values analysed by the Theoretical stress concentration factor (Kt).

Therefore, an alternate factor came in introduction to account this reduction; called Fatigue stress concentration factor (Kf).

Theoretical stress concentration factor (Kt) Kt = σmax/σ0 = τmax /τ0

Fatigue stress concentration factor (Kf)

Kf = (Endurance limit of the notch free specimen) /(Endurance limit of the notched specimen)

Kf or Fatigue stress concentration factor has a practical significance and therefore observed in all actual materials. Value of Kf depends on the grain size of the material. Fine grained materials experience greater reduction in endurance limit than Coarse grained materials due to stress concentration.

NOTCH SENSITIVITY : DEFINITION AND SIGNIFICANCE

Defined as the susceptibility of a component to succumb to the damaging effects of stress causing notches in fatigue loading conditions.

Factor governing this effect came to be known as Notch Sensitivity Factor (q).

q = (Inc. of Actual stress over Nominal stress)/(Inc. of Theoretical stress over Nominal stress)

Now,

σ0= Nominal stress (As obtained from elementary equations)

Actual Stress = Kf σ0

Theoretical Stress = Kt σ0

Inc. of Actual stress over Nominal stress= Kf σ0 – σ0

Inc. of Theoretical stress over Nominal stress=Kt σ0 – σ0

Therefore,

q = (Kf σ0 – σ0) / (Kt σ0 – σ0) = σ0 (Kf – 1) / σ0 (Kf – 1)= (Kf – 1)/(Kt – 1)

Above equation can be modified as:

Kf = 1+ q(Kt – 1)

CONCLUSION :

1) When the material has no sensitivity to notches :

q=0 and Kf=1

2) When the material fully sensitive to notches :

q=1 and Kf= Kt

The experimental values of q for Reversed axial & bending stresses & Reversed torsional shear stresses can be taken from the design charts as per given IN DESIGN DATA BOOK MANUAL as well as DESIGN OF MACHINE ELEMENTS : V B BHANDARI book.

IN CASE OF DOUBT IN VALUES, For safe design , we should always take q=1 and Kf= Kt.