A power screw is a mechanical device that is used for converting rotary motion into linear motion and transmitting power. Power screw is also called a translation screw. Power screws are screws that either receive power or which transmit power. Power screws are different from screw fasteners (normal screws)in design.

They must have sufficient strength to transmit power. They should have an adequate bearing area to withstand forces. There are three essential parts of the screw viz., screw, nut, and a part to hold either the screw or the nut in its place.

Thread Profiles of Power Screw:-

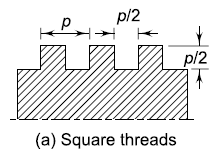

1)Square threads:-The square threads are a common screw thread, which is used in high load applications such as leadscrews and jackscrews.

Advantages of square threads are:-

- The efficiency of the square is more than that of trapezoidal thread.

- There is more radial pressure or side trust on the nut

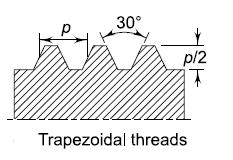

2)Trapezoidal threads:– Trapezoidal threads are screw threads with trapezoidal outlines. It is the most common form used for power screws.

Advantages of Trapezoidal threads are:-

- It offers high strength and ease of manufacture.

- The trapezoidal thread has more thickness at its core diameter than that of square thread.

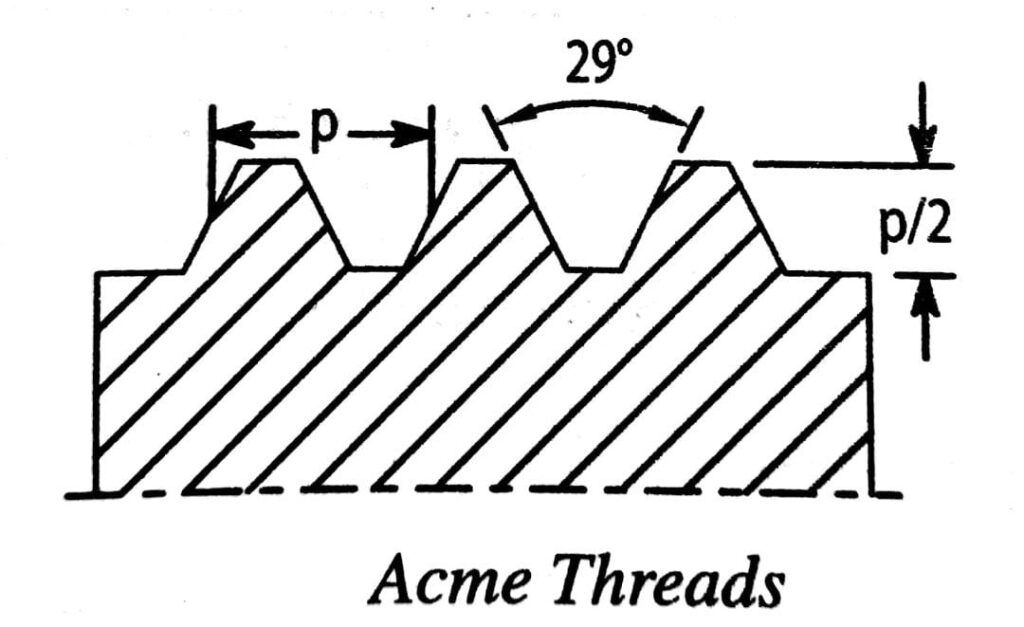

3)Acme Thread:- Acme thread is a special type of trapezoidal thread. The thread angle of acme thread is 29°.

Advantages of Acme Threads:-

- Acme threads have a large load carrying capacity and economical to manufacture.

- Acme Threads offer high strength.

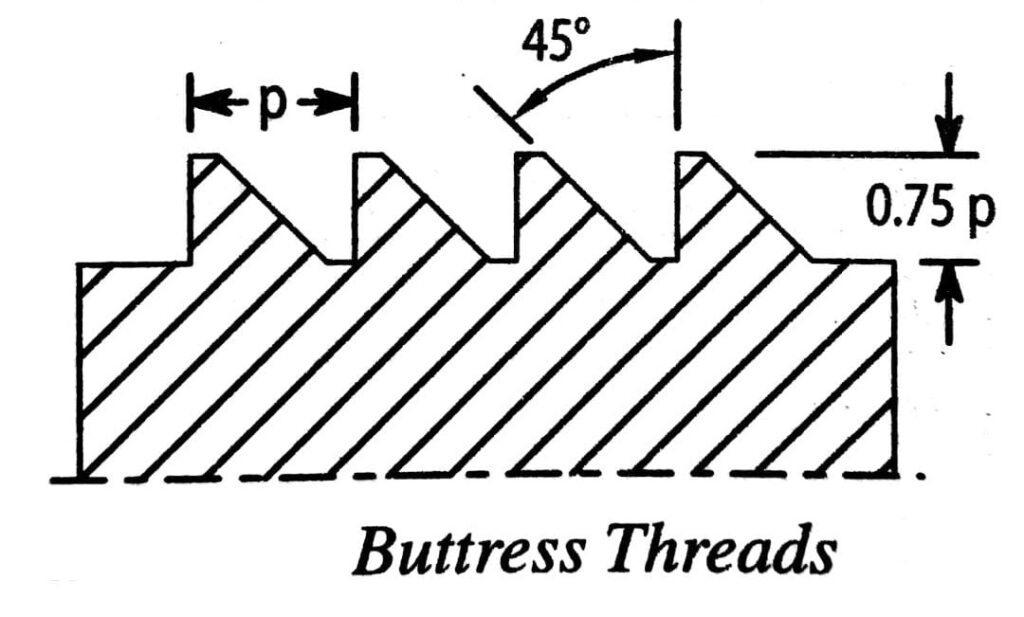

4)Buttress thread:– It is another thread that is used where the heavy axial force acts along the screw axis in one direction only.

Advantages of Buttress thread:-

- It has higher efficiency compared with trapezoidal threads.

- It can be manufactured economically on a thread milling machine.

- Buttress thread is stronger than any other screw thread.

Application of power screw:-

1)Rising or lowering the load.

Example:- Screw jack

2)Obtaining required motion in machine machining operations.

Example:- The lead screw of the lathe.

3)To clamp a workpiece. example:- A vice.

4)To load a specimen.

Example:- Universal testing machine

Advantages of power screw:-

- Large load-carrying capacity.

- Simplicity in design.

- Overall dimensions of the power screw are small resulting in a compact construction.

- Manufacturing is easy.

- A power screw gives smooth and noiseless service.

- There are a few parts in the power screw. this reduced costs and increase maintenance.

- Possibility of obtaining very slow motion.

Disadvantages of power screw:-

- Poor efficiency less than 40%.

- Rapid wear.

- High friction.