SPIRAL SPRINGS:INTRODUCTION

SPIRAL SPRINGS: It is one of the most commonly used springs in various small scale and large scale industrial uses. It’s basically a spring consisting of a wire coiled usually in a flat spiral or in a helix. Also known as “Power spring” OR “Flat spiral spring”.

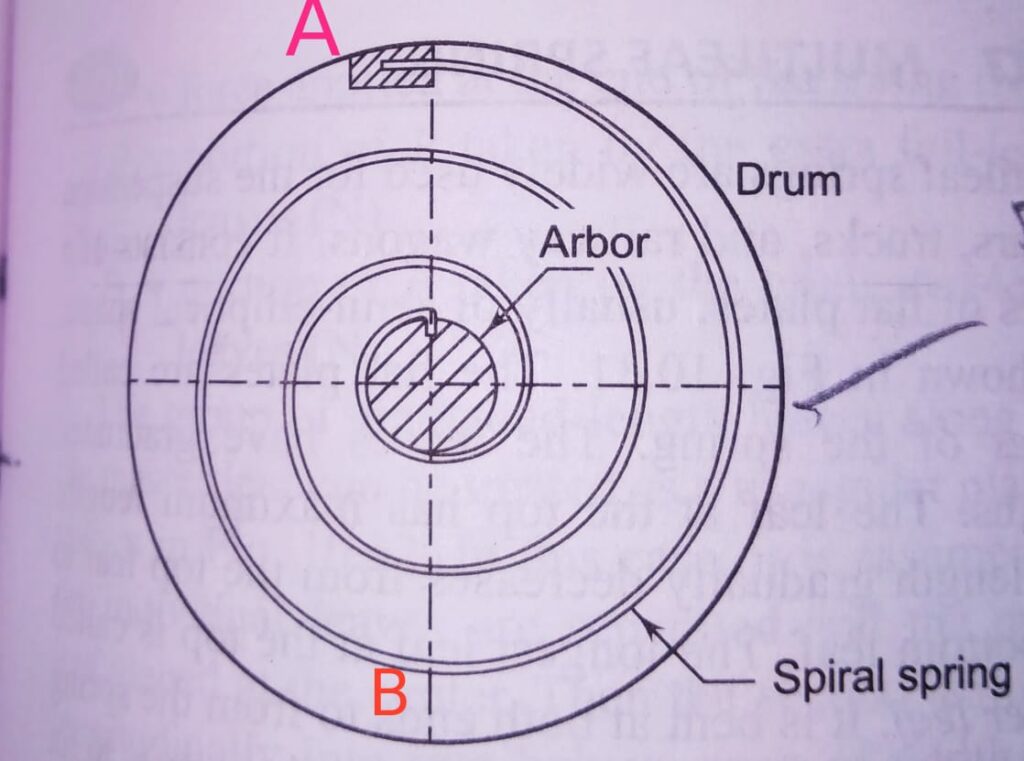

STRUCTURE OF SPIRAL SPRINGS :

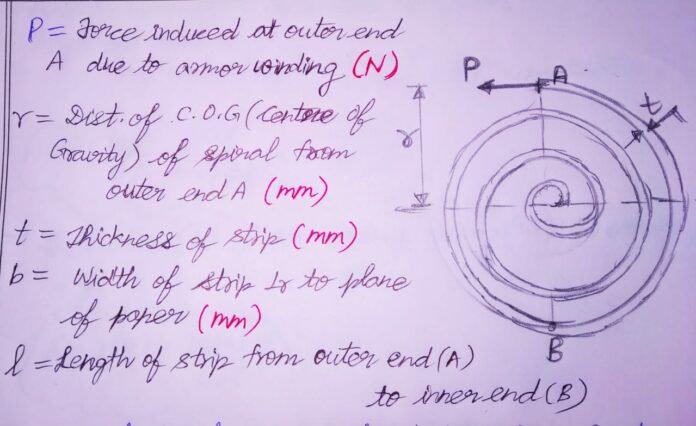

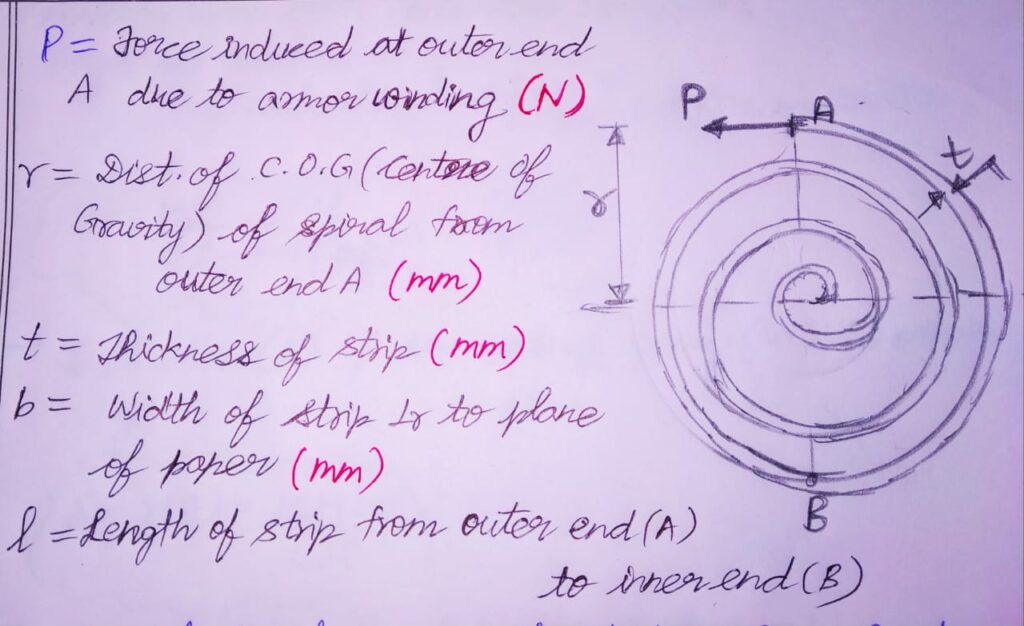

A Spiral spring consists of a thin strip of Rectangular cross section, wound in the form of Spiral as shown. Inner end of this wound strap fixed in the arbor which located at the center. Whereas, the outer end clamped to the drum , called ‘Retaining Drum’. The spring wounds up due to rotation of the arbor.

WORKING :

Due to rotation of arbor, the spring wounds up in the process. During this process, Energy gets stored up in the spring. This energy gets released as mechanical Torque through the drum during unwinding of spring through rotation.

The Strip is made of High Quality Steel. The strip, being very thin, provides high flexibility and enables arbor to have larger angular deflection.

In many applications, the angular deflection of arbor crosses several dozens of revolutions(N). Moreover, these results in storing considerable amount of energy.

Very often, Drum mostly made integral with a Gear. Here, energy released by rotation of this Gear to another Gear which drives a mechanism.

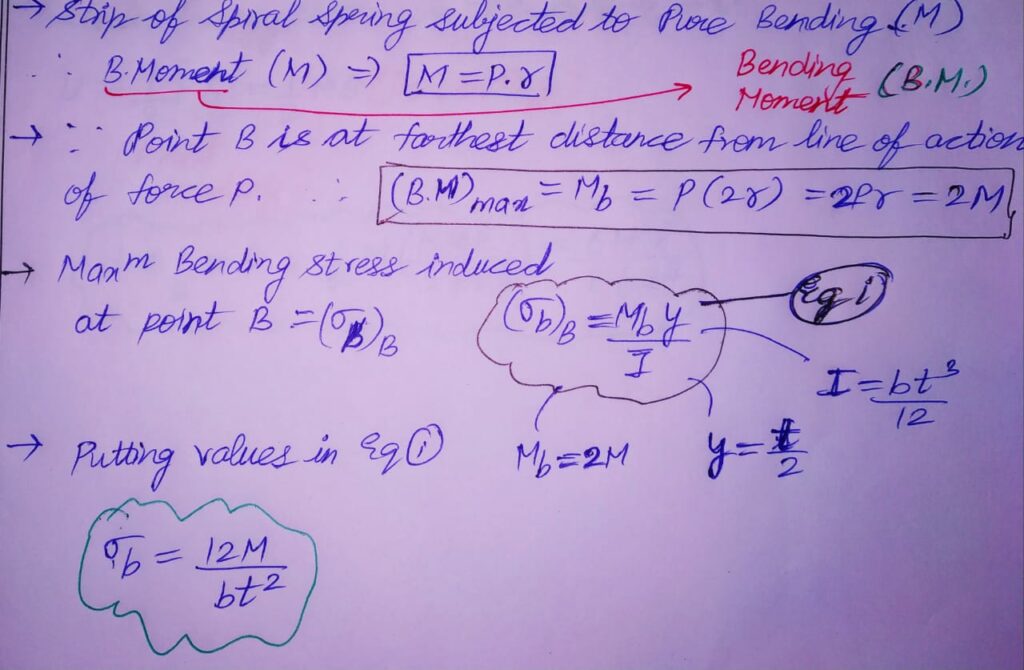

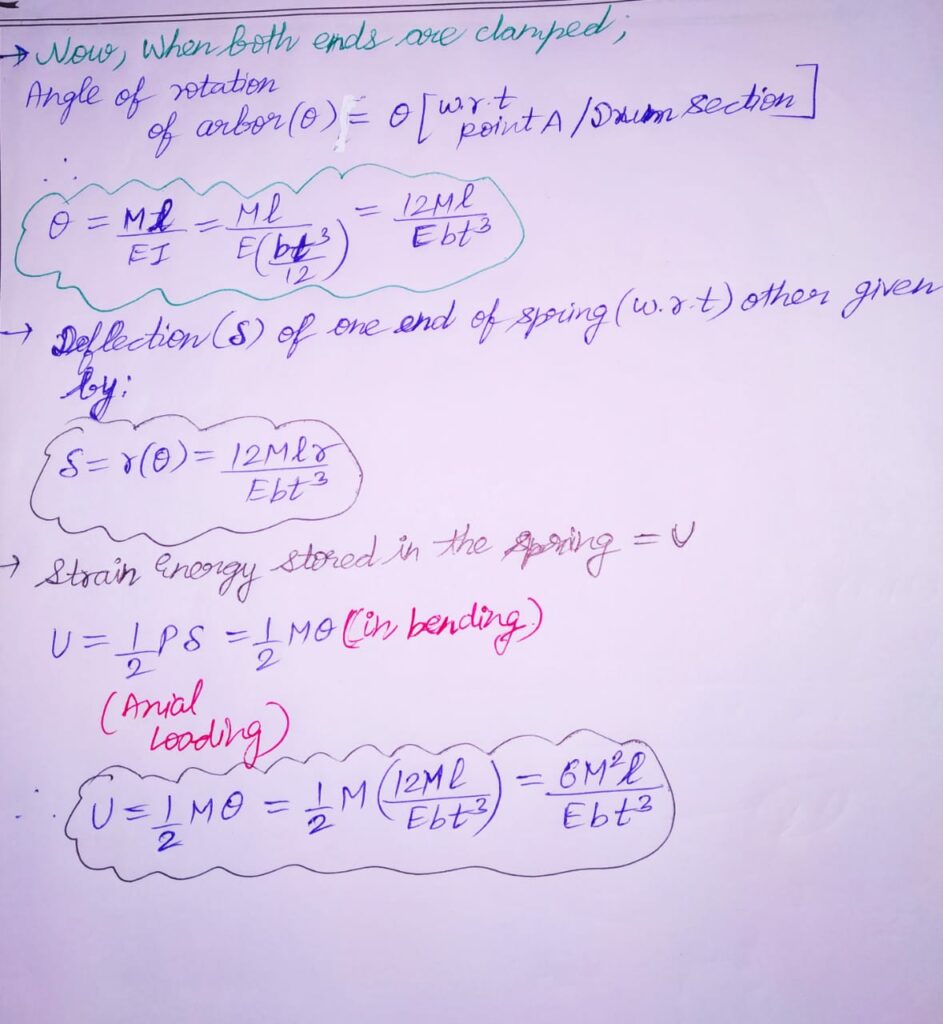

DERIVATION AND FORMULAE:

APPLICATIONS:

Spiral springs are used in the following applications:

1) Watches and Cameras

2) Automatic Weapons

3) Toys (Mostly used)

4) Starters for small engines

NUMERICALS :

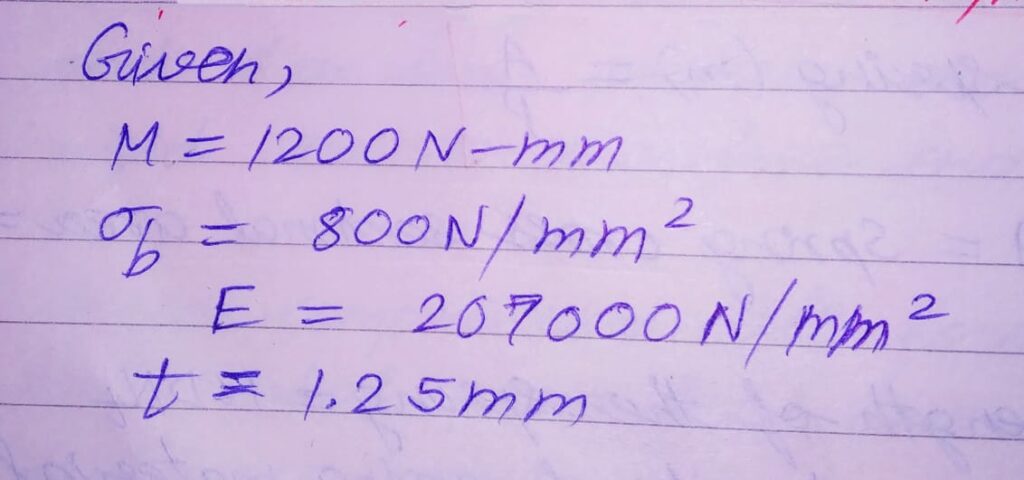

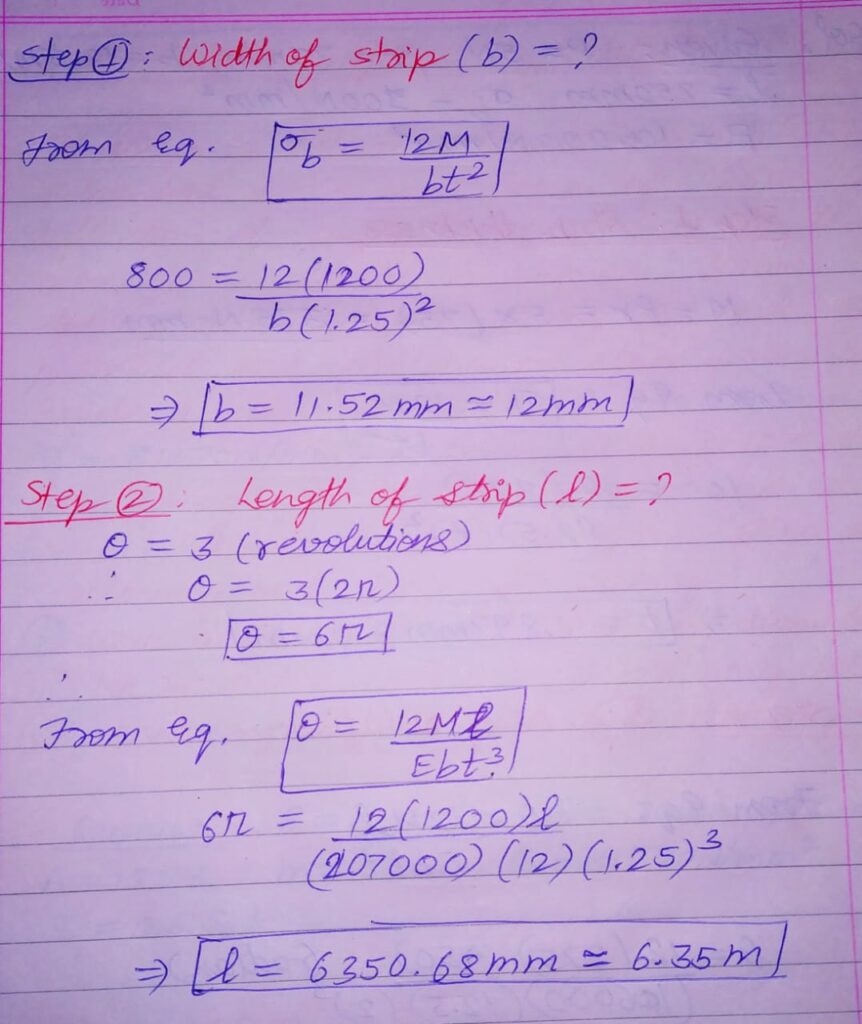

Q1. A flat Spiral Spring given here. It is subjected to a Max. torque of 12000 N-mm. Spring made of steel strip and the max. bending stress should not exceed 800 N/mm2. When the stress in the spring decreases from 800 N/mm2 to 0 N/mm2, the arbor turns down three complete revolutions w.r.t the drum. Thickness of steel strip = 1.25 mm and Modulus of Elasticity= 207000 N/mm2 . Calculate the width and length of steel strip.

SOLUTION: