Introduction of a Steam Generator/Boiler

A Steam Generator is one of the most important working substances in the engineering field. Steam is basically required for power generation, process heating, and space heating applications. Low pressure and wet steam are used in chemical and processing industries for heating purposes and high-pressure superheated steam is used for power generation to run prime movers.

The type of equipment used to produce the steam is called Steam Generator or Boiler. This type of Generator also known as a Boiler is a closed vessel strongly made of high-quality steel, in which steam is generated from water by the applications of heat.

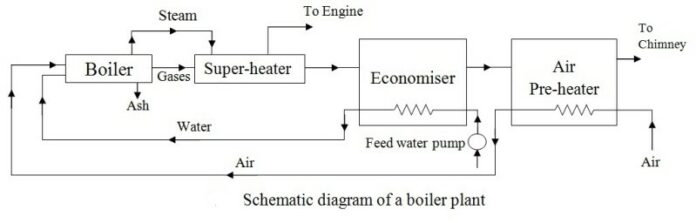

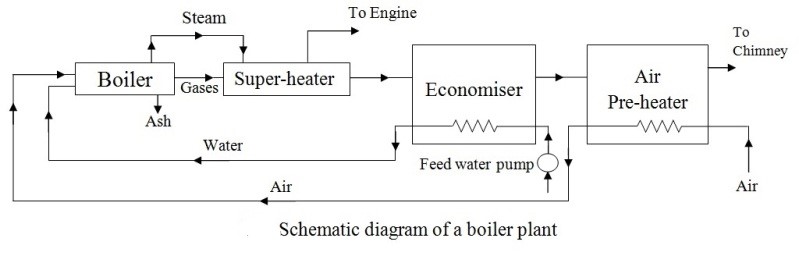

In a boiler, there is a combination of apparatus for producing, furnishing, or recovering heat together with the apparatus for transferring the heat so made available to water which could be heated and vaporized to steam form.

The function of this boiler is to transfer the heat produced by a combination of fuel, to water and thus produce steam.

Working on a Boiler/Steam Generator

The hot gases are formed by burning fuel. The fuel may be solid, liquid, or gas. The heat of combustion is transferred to the water inside the boiler and water is converted to steam. The steam is collected over the water surface and taken out from the boiler through the steam separator.

This steam by suitable pipes used to drive engines or turbines or used for industrial heating purposes. The above operation of producing steam is not so simple but needs a number of parts for safe and efficient operation. These parts are referred to as mountings and accessories.

Requirements for Good A Boiler/Steam Generator:-

- The boiler should be capable to generate steam at the required pressure and quantity with minimum fuel consumption and in minimum time.

- The initial cost, installation cost and maintenance cost of a boiler should be low.

- A good boiler should be light in weight, and capable of quick starting.

- The boiler should occupy a small floor area.

- It should meet the fluctuating demands of steam and pressure without overheating and fluctuations.

- The joints of the boiler should be leakproof to avoid any explosion.

- Installations on site should be easy and with minimum labor.

- There should be no deposition of any foreign particles and mud on the inside and heating surfaces.

- It should conform to the safety regulation as laid by the “Boiler Act.”

Uses:-

Boilers are used to produce steam. The generation part of a steam system uses a boiler to add energy to a feedwater supply to generate steam.