As the name implies, the two-stroke engine only requires two-piston movements (one complete cycle) to generate power. The cycle is completed in two-stroke i.e., one revolution of the crankshaft. Only two-piston stroke is required to complete the process, one for compressing the fresh air-fuel mixture and the other for expansion or power stroke.

The main difference between two-stroke and four-stroke is in the method of filling the fresh air-fuel mixture in the cylinder and removing the burned gases from the cylinder. The engine can produce power after one cycle because the exhaust and intake of the gas occur simultaneously. Cycle complete all strokes in one revolution and rotates 360 degrees to complete the processes.

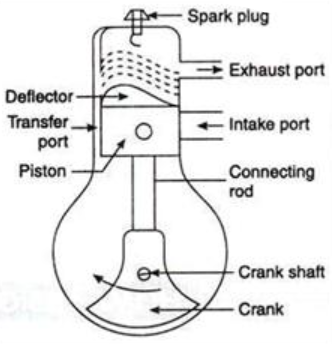

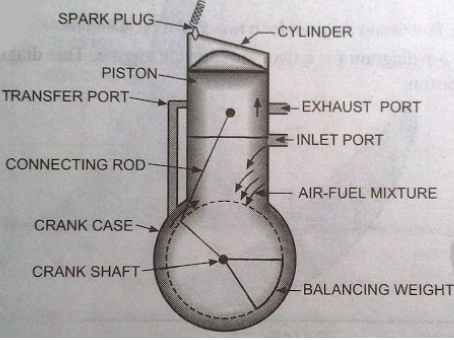

Construction of Two Stroke SI Engine:-

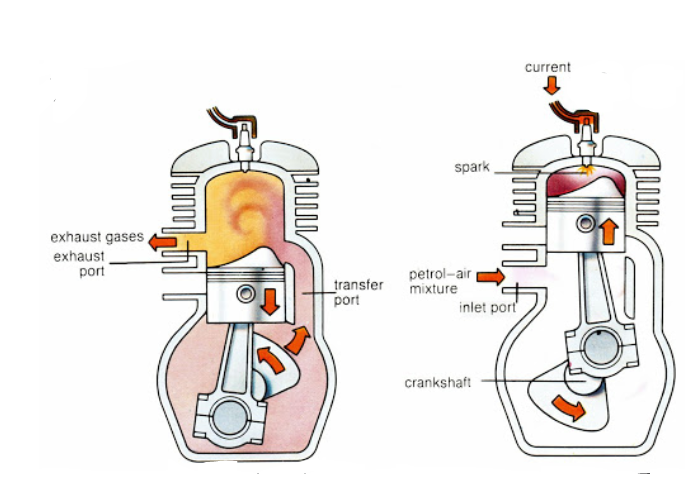

The two-stroke SI engine consists of a cylinder whose one end is fitted with a cover for the placement of spark plug and the other is fitted with the crankcase. There are three ports in the cylinder i.e., an inlet port, exhaust port, and transfer port. The opening and closing of these ports depend on the piston movement.

A flywheel is a mechanical device that is used to store energy and a spark plug is used to delivers electric current to the combustion chamber which ignites the air-fuel mixture. In a two-stroke engine, we get Power from expansion stroke. The size of a flywheel in four-stroke is bigger than a two-stroke.

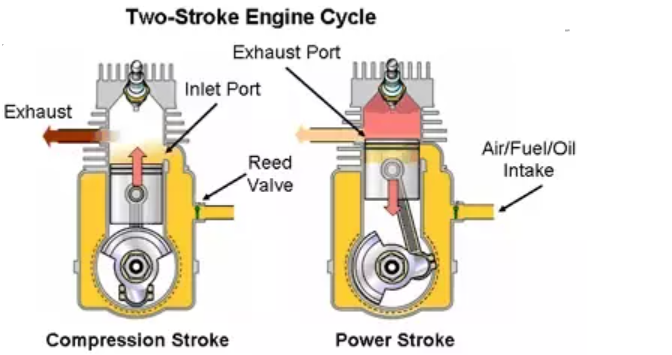

Basically, there are two processes in two stroke SI engine:-

1) Suction + compression :-

When the piston moves from BDC to TDC the inlet port opens and the fresh air-fuel mixture enters easily due to less pressure inside the crankcase(cylinder). During this, the transfer port remains closed. But as soon as the piston reaches TDC, the air-fuel mixture which already present in TDC compressed and the spark plug ignites the compressed fuel. Now power stroke begins.

2)Power Stroke (Expansion + Exhaust) :-

Now, due to high pressure in TDC, the piston moves from TDC to BDC. The Inlet port will be closed and the exhaust port will be open. Transfer port also opens. Now, the fresh air-fuel mixture moves upwards through the transfer port and the exhaust gases move outward.

When the piston moves TDC to BDC pressure inside the crankcase increases, due to which fresh air-fuel mixture comes above the piston through the transfer port and pushes the exhaust gases due to which exhaust gases exit through the exhaust port. The process is known as scavenging.

During the scavenging process, part of the air-fuel mixture also exits through the exhaust port. Hence, to reduce this, the piston is provided with the Crown shape.

Losses in the two-stroke engine:-

1)During the scavenging process part of the fresh air-fuel mixture also comes out through the exhaust port.

2)When the fresh air-fuel mixture comes above the piston through the transfer port then part of lubricant also flows with it, due to which:-

- Friction loss increases.

- Compression efficiency of fuel decreases.