STRESS CONCENTRATION- INTRODUCTION:

Why Sudden cross section variation (Stress Concentration study) was necessary to study for component design????????????

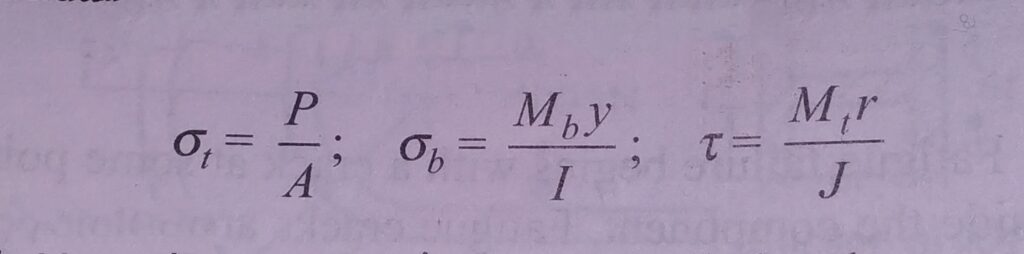

Basic stress equations given below as:

These stress equations are ELEMENTARY EQUATIONS. Also, Equations derived here involves taking a set of particular assumptions.

One such assumption is : There are no discontinuities in the cross sectional area of an element . But, we know, in practicality , this is just an ideal case.

Many basic machine elements,such as key ways and splines,screw threads etc. consists of sudden bends and edges(i.e .sudden cross section changes). Design of such machine elements requires specific rules and sets.

DEFINITION(IS IT RELATED TO CROSS SECTION?????):

Stress concentration is defined as the “localisation of high stresses in a machine element due to irregularities or abnormalities present in the element and abrupt cross section changes”.

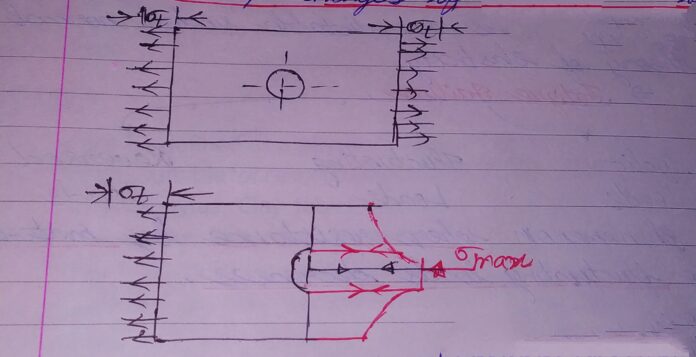

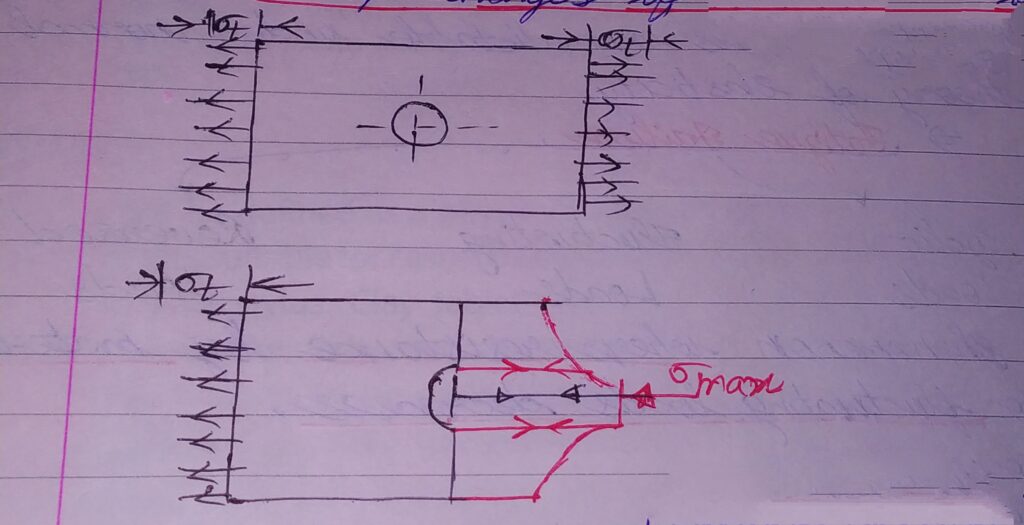

Consider a plate with a circular hole cut at the centre , and also subjected to tensile stress.

Using Photo elasticity technique, we find out stress distribution near the holed section.

We find that stress lines are more crowded at the vicinity of the holed section, rather than in the other regions.

Crowded stress lines indicate the sudden change in stress magnitude at a section.

These stresses when calculated came out be more than the values found out by ELEMENTARY EQUATIONS.

The resultant increase in stress is due to the phenomenon called “STRESS CONCENTRATION”.

STRESS CONCENTRATION FACTOR(Kt)

Stress concentration , being internal phenomenon cannot be directly found. To consider the effects of stress concentration and localised stresses, a factor came in study known as Stress concentration factor, represented by Kt.

Defined as the ratio of Highest value of actual stress near discontinuity TO the Nominal stress which is obtained by elementary equations.

Kt=Highest value of actual stress near discontinuity / Nominal stress obtained by elementary equations.

Kt=σmax /σ0= τ max /τ 0

σ0 &τ 0=Nominal stresses as well as min. cross section stresses from Elementary equations

σmax & τ max = Localised max. stresses near discontinuity.

Kt also known as “THEORETICAL STRESS CONCENTRATION FACTOR”

CAUSES OF STRESS CONCENTRATION (CROSS SECTION VARIATIONS??) :

1.VARIATION IN MATERIAL PROPERTIES :

Homogeneous composition materials are mostly preferred for design. But, in practice, there are various factors of variation in material properties :

a)Due to internal cracks and flaws like blow holes

b) Presence of Weld portion cavities

c) Due to air holes in steel components

d)Foreign element entry (interstitial condition)

These factors causes cross section discontinuities.

2. LOAD APPLICATION:

Usually forces and loads acts on the machine. These loads are either Point contact loads or small areal contacts. Since, loads act on a small area, high pressure acts here,which causes high stress at these points. This causes stress concentration.

Examples of load application:

- Contact between meshing teeth of Driving gear and the Driven gear.

- Due to contact b/w Cam and Follower.

- Because of contact b/w Races and Balls of ball bearing.

- Due to contact b/w Rail and Wheel.

3.ABRUPT CHANGES IN SECTION :

To connect a transmission shaft with another element (gears, pulley,bearings) , usually key-ways are cut on shaft as well as shoulders. These causes sudden cross section changes which leads to high stresses at these regions. This brings stress concentration.

4. MACHINING AND OTHER SCRATCHES:

Usually, machining inspection seals, stamp marks or physical certifications are taken as surface irregularities.These causes stress variations at its vicinity leading to stress concentration.