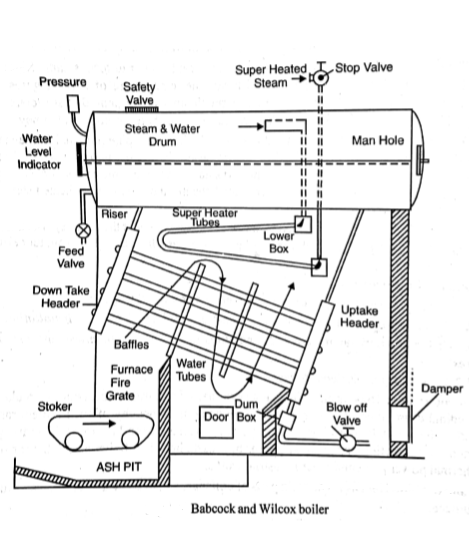

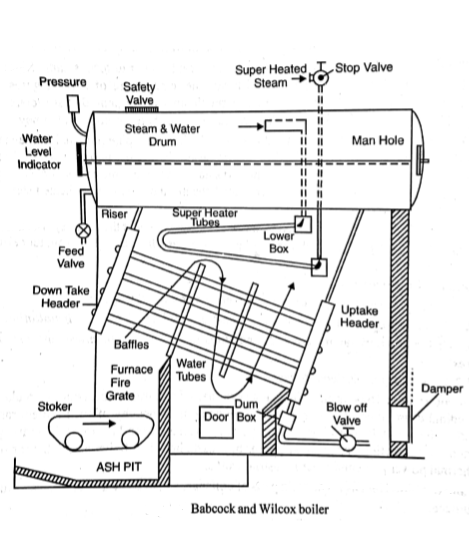

Introduction of Babcock and Wilcox Boiler

Babcock and Wilcox Boiler is an externally fired, water tube, natural circulation, longitudinal drum, type of stationary boiler. The evaporative capacity of each boiler ranges from 20,000 to 40, 000 kg/hr of steam, and operating pressure from 11.5 to 17.5 bar is quite common.

But sometimes pressure may be as high as 42 bar. This boiler is suitable for small size thermal power plants and order industrial works.

Construction of Babcock and Wilcox Boiler

The main parts of the boiler are the steam and water drum, water tubes, and furnace

Steam and water drum:-

The steam and water drum is made up of small shells riveted together to form a long drum. All mountings i.e., water level indicator, steam pressure gauge, fusible plug, safety valve, etc. are mounted on the drum.

Water tubes, Riser and downcomer:-

Below the drum, there is a number of water tubes connected with each other and with the drum by vertical passage, called uptake and down take. Uptake is also called Riser.

Mudbox, Blow off cock:-

The downcomer is joined at the bottom to a mud box, which has a blow-off cock for cleaning of sediments and deposits in a mud box.

Superheater tubes and steam stop valve:-

There are additional sets of U shape horizontal tubes between the drum and the water tubes. These are used to superheat the steam and known as superheater tubes. From the superheater, superheated steam is available at the stop valve.

Furnace, fuel feed hopper mechanical stoker:-

Below the uptake header, the furnace of the boiler is arranged. At the front end of it, there is a fuel feed hopper and a mechanical stoker is arranged below the hopper. There is a “bridge wall deflector” which deflects the combustion gases upwards, then downwards then again upwards before escaping to the chimney.

Smokebox, chimney, dapper:-

The smokebox is fitted at the back of the Furnace. The chimneys fitted at the top of the smokebox. A damper is placed at the inlet of the chimney to regulates the draught.

Working of Babcock and Wilcox Boiler

The hot combustion gases caused by the burning of fuel on the grate rise and are deflected upwards by the bridge wall deflector and pass over to the front portion of the tubes and drum. This completes the first pass. With bafflers, they deflect downwards and complete the second path.

Again they rise upwards by bafflers and complete the third pass and finally, they go out to the atmosphere through the chimney. During their path of travel, they transfer their heat to the water inside the tubes, and water converted into steam.

Now, the steam collected in steam space is allowed to enter into the superheater tubes and steam gets superheated. This superheated steam is finally supplied to the engine through a steam stop valve. Feedwater is supplied by a feedwater inlet pipe. The steam is escaping through the water to the upper half of the drum.

The cold water flows to the rear header and thus completes the cycle. Here water is circulated by natural circulation set up by temperature difference.

Advantages of Babcock and Wilcox Boiler

- The evaporative capacity is high 20,000 to 40,000 kg/hr and the operating pressure range from 11.5 to 17.5 bar.

- The defective tubes can be replaced easily.

- The draught loss is minimum and efficiency is high.

- While the structure is independent of brickwork and hence boiler may be expanded or contract easily.

- The brick walls only provided to enclose the furnace and to passage the hot gases.

Disadvantages of Babcock and Wilcox Boiler

- The main disadvantage of Babcock and Wilcox Boiler is less suitable for impure and sedimentary water, as a small deposit of scale may cause the overheating and bursting of tubes. Hence, water treatment is very essential for water tube boilers.

- Failure in feed water supply even for a short period is liable to make the boiler overheated. Thus the water level must be watched very carefully during the operation of a water tube boiler.

- The maintenance cost is very high