HELICAL TORSION AND MULTILEAF SPRINGS

Helical Compression and Extension springs had been discussed in the previous blog.

To study that blog, follow the link given below:

https://mechomotive.com/spring/

Now, let’s come to the study of the HELICAL TORSION SPRINGS , its structure, function and applications.

HELICAL TORSION SPRINGS:

Helical torsion springs seems quite similar to Helical Compression OR Extension springs but has some changes.

Here, torsion springs shows the property that its ends made in such a way ,so that the spring undergoes loading by a torque, acting along the axis of the coil.

Basically , it’s a modification of the Helical Compression/Extension Springs.

These torsion springs main function is to used to transmit torque to a particular component in a mechanism.

STRESS CHARACTERISTICS IN TORSION SPRINGS:

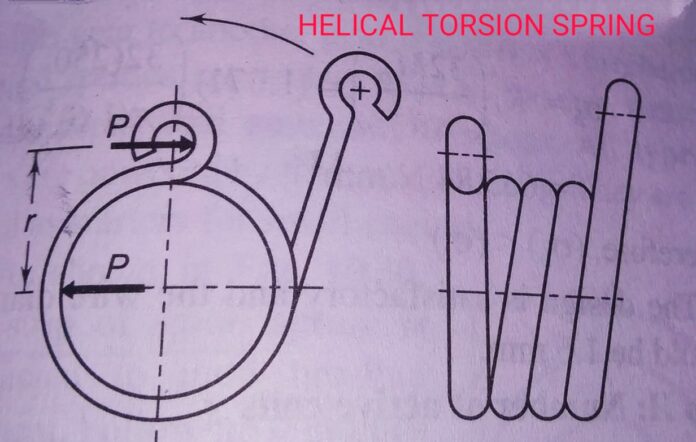

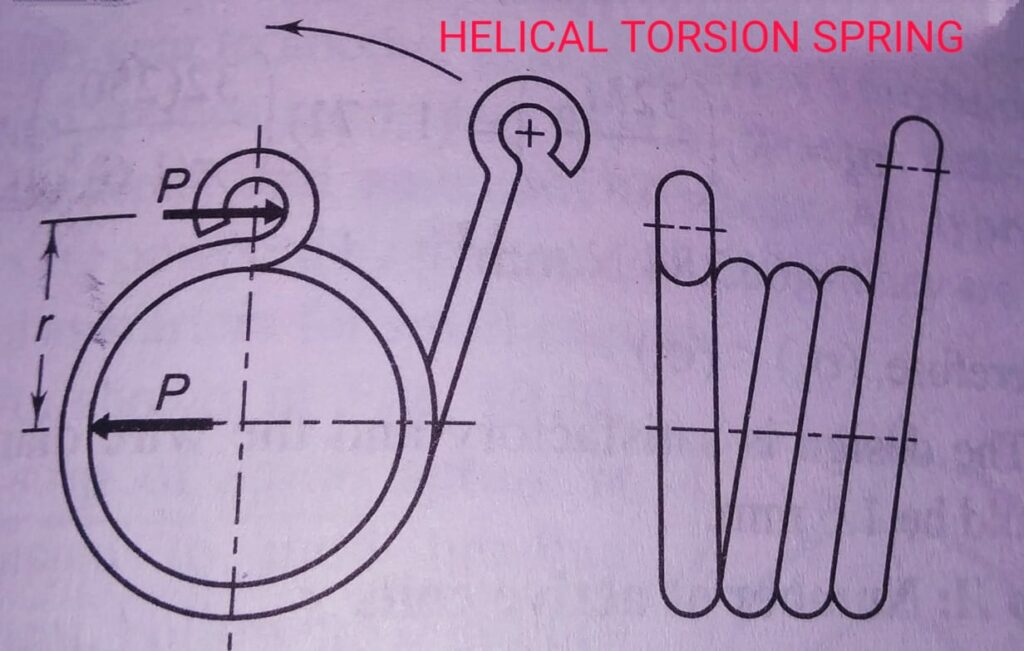

A Torsion spring shown as below has this particular design:

This springs transmits a torque of (P*r) . Due to this ,this spring resists this Bending moment (P*r) which tries to wind up the spring. This bending moment induces bending stresses in the spring wire.

CONCLUSION:

According to the observation , we conclude that the term “torsion spring” seems somewhat meaningless. Because, here the wire induces bending stresses in it due to bending moment, unlike torsional shear stresses as came in Helical Compression/Extension springs. Here, although Effort was torsional moment, but output came out as bending stresses and not torsional shear stresses.

APPLICATIONS :

These springs are used in following:

1) Door hinges & Door locks

2) Brush holders

3) Automobile starters

4) Retractable Seating

MULTI LEAF SPRINGS:

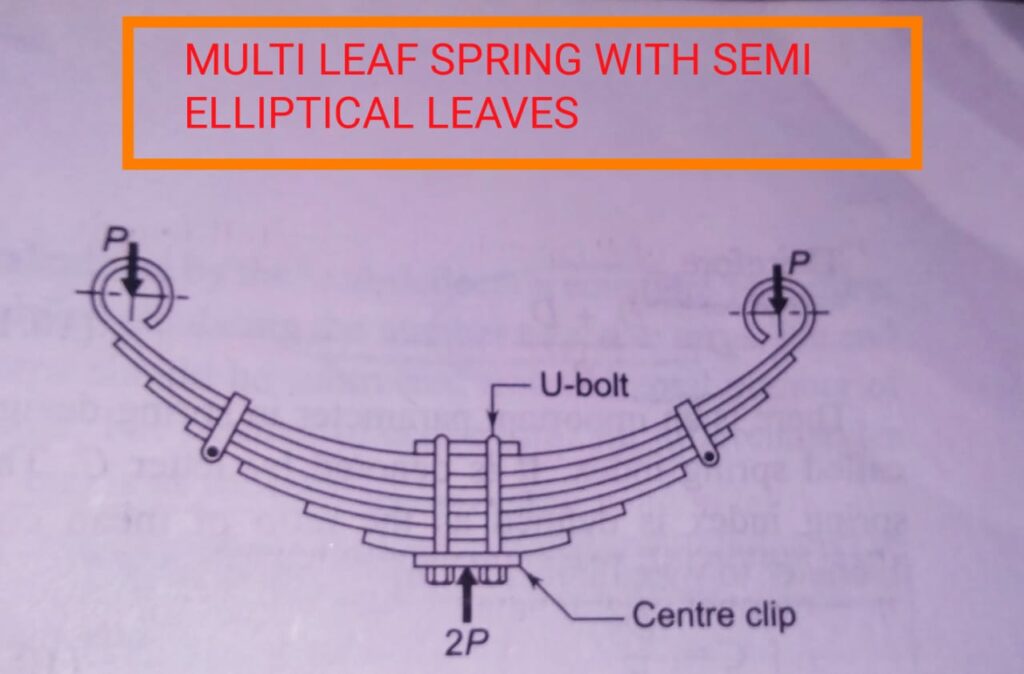

Also called a Laminated spring, it consists of a series of flat plates , usually of semi-elliptical shape. These flat plates, called leaves , have varying lengths. These leaves are held together by means of U-Bolts and Center clip. Two bolts made to insert through these eyes to fix the leaf spring to the automobile body

The longest leaf of all leaves usually called the MASTER LEAF.

This MASTER LEAF now bended at the two ends to form spring eyes. Bending stresses subjected to the leaves of the Multi leaf springs.

APPLICATIONS:

Multi-leaf springs find wide usage in as automobile and rail road suspensions.