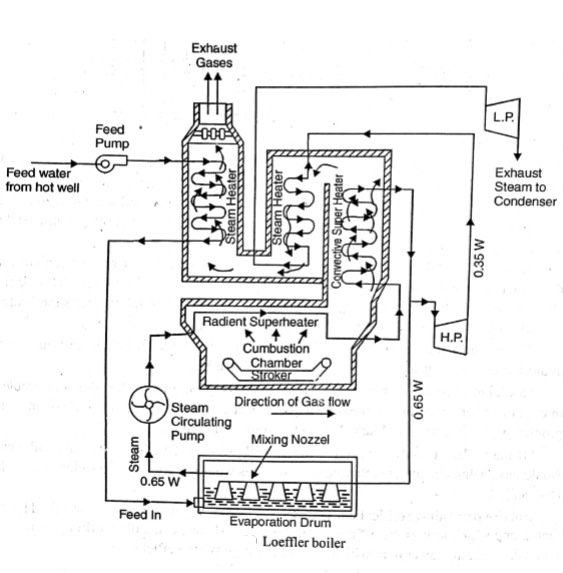

Loeffler boiler is a water tube boiler and also used for forced circulation of water. It is used for superheated steam and power generation. This is a high-pressure boiler that produced pressure up to 100 bar.

Both the LaMont and Loeffler boiler generates steam with the use of saltwater but in the Loeffler boiler, there is no problem with Salt and sediment under the boiler but in the case of the LaMont boiler there is a problem of salt and sediment under the boiler surfaces.

The main components of Loeffler Boiler

1)Feed pump:- The main function of Feed pump is to feed the water to the main system.

2)Air preheater:- The air preheater preheats the air before sending it to the combustion chamber.

3)Blower:- It supplies hot air.

4)Economizer:- It preheats the feed water before entering into the evaporating drum and the economizer increases the boiler efficiency.

5)Evaporating drum:- It is placed at the lower position of the boiler. It contains the mixing nozzle. Here the feed water is converted into saturated steam with the help of the superheated steam from the superheater.

6)Steam Circulating Pump or Centrifugal Pump:- It is present in between the evaporating drum and radiant superheated. It circulates the steam into the boiler.

7)Radiant Superheater:- It superheats the steam with the help of radiation produced by the burnt fuel in the boiler.

8)Convective Superheater:– It superheats the steam to the desired temperature of above 500 degrees celsius.

9) Turbine:- The superheated steam is sent to the turbine blade for rotation and the blade is attached to the shaft which also rotates and, is connected to the induction motor for the generation of electricity.

10) Mixing Nozzle:– It is present inside the evaporating drum. The main function of mixing nozzles is to mix the steam from the superheater with feed water and evaporates them.

11)Chimney:- The function of chimneys is to exhaust the burnt gases into the atmosphere.

12)Water Level Indicator:- It indicates the water level inside the boiler.

13)Fusible plug:- It protects the boiler against damage due to overheating.

Working of Loeffler Boiler

The feed water from the economizer tubes is forced to mix with the superheated steam in the evaporating drum. The mixing nozzles are provided in the evaporator drum. The two-third (70%) of superheated steam from the superheater enters into the drum nozzles. The nozzles mix this superheated steam with feed water. This converts the feed water into saturated steam.

The saturated steam thus formed is passed through Radiant superheated. Now, the steam is routed to the Convection superheater. This stem then passes through the tubes of the combustion chamber wall and then enters the superheater.

Now from the superheater about 1/3rd of superheated steam now can be used for rotating the turbine blade for the generation of electricity. So the remaining amount about 2/3rd of steam is sent to the evaporating water.

Advantages of Loeffler boiler

- Saltwater is used for the generation of steam is a major advantage of the Loeffler boiler.

- The size of the boiler is very compact.

- It created less sound.

Disadvantages of Loeffler Boiler

The evaporating drum is costly and Bulky in size.

Bubble formation occurs which creates a problem of Heat transfer rate.