REDUCTION IN STRESS CONCENTRATION

STRESS CONCENTRATION STUDY

Study of stress concentration is similar to FLOW ANALOGY

FLOW ANALOGY

Used for both study of velocity distribution(fluid flow) and stress distribution(stress material)

REDUCTION OF STRESS CONCENTRATION

1.UNDERCUTTING

2.FILLET RADIUS

3.REDUCTION OF DIAMETER

4.MATERIAL REMOVAL

REDUCTION IN STRESS CONCENTRATION: IS IT IMPORTANT FOR DESIGN???

Reduction of stress concentration: Practically,we cannot eliminate effect of stress concentration completely from a component. But, we can reduce it to an extent through various methods. Specific geometry given to the component so that stress concentration decreases.

ANALYSIS OF STRESS CONCENTRATION: CONCEPT OF FLOW ANALOGY

The FLOW ANALOGY concept came for usage as a golden tip for study of stress concentration of a component.

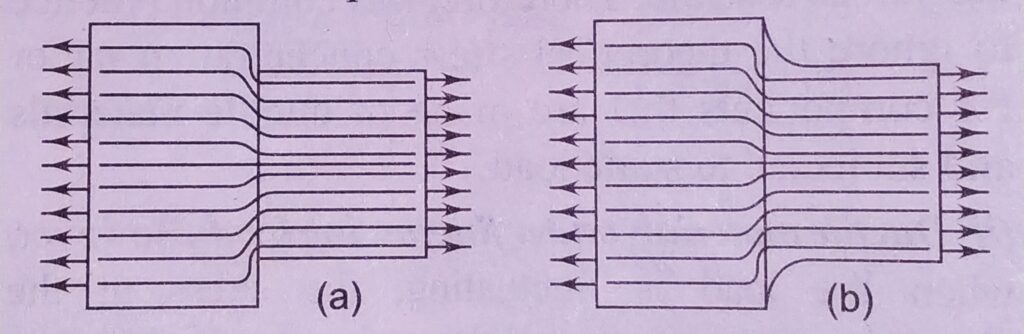

Velocity distribution due to a fluid flow in a channel seemed similar to the stress distribution in an axially loaded plate.

Moreover, equation for both fluid flow and stressed system also came out similar and same.

So, FLOW ANALOGY BECAME A GOOD ANALOGY SYSTEM FOR STRESS DISTRIBUTION STUDY.

STRESS SYSTEM:

FLOW ANALOGY:

FLUID FLOW:

An uniform cross sectional and dimensional fluid channel taken for study. Here, uniform velocity flow is seen and equally spaced streamlines. The flow through any cross section along channel , as per theory ,given by:

Q= ∫u dA

An uniform cross sectional and dimensional stress induced plate taken for study. Here, uniform stresses can be seen and equally spaced stress lines.The stress through any cross section along the plate , as per theory , given by:

P=∫σ dA

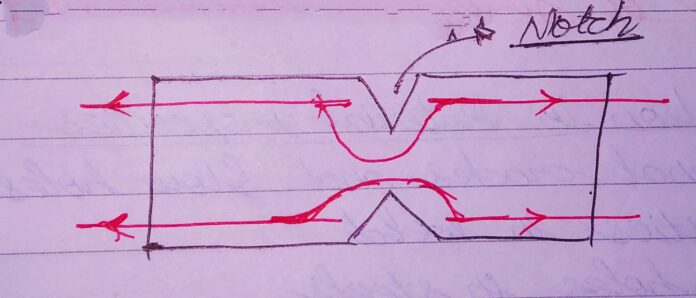

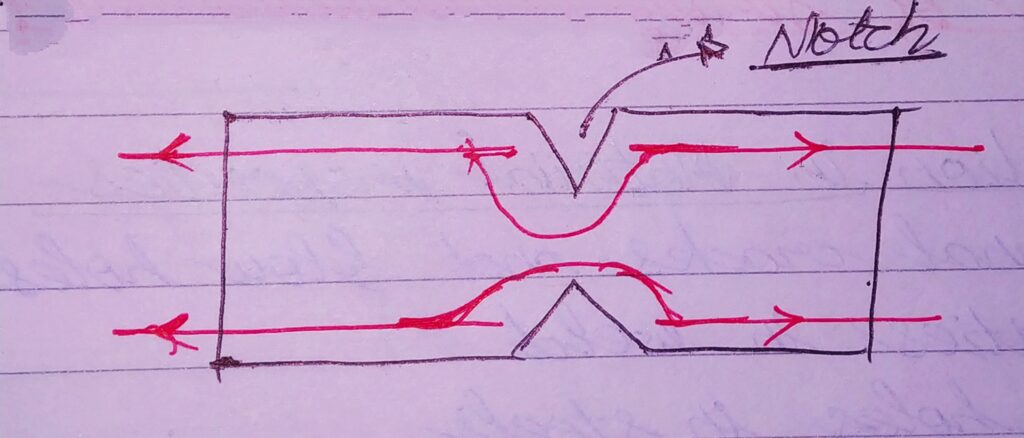

FOR STRESS SYSTEM, when Cross Section suddenly reduces, stress lines becomes more dense in order to transmit the same force. At cross section changes, these lines tend to bend away. Due to sudden cross section changes , these bending of lines become very sharp and then stress concentration occurs.

In order to reduce stress concentration, CORNERS (SUDDEN CROSS SECTION CHANGES AREAS) made rounded so as to prevent sharp bending of stress lines. Often called “streamlining“, this method helps in better reduction of stress concentration in mechanical components.

METHODS OF REDUCTION OF STRESS CONCENTRATION :

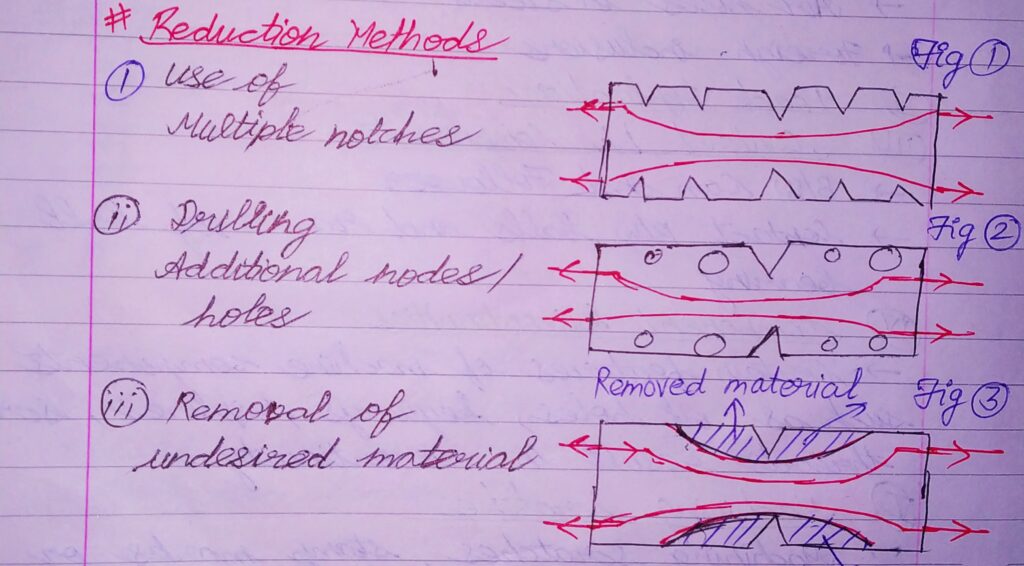

A) Additional notches and holes in Tension loaded members for reduction:

Usually , a single notch in a tension induced member leads to high degree of stress concentration (since sudden cross section change occurred).

This problem found its solution with following methods of stress concentration reduction:

1.Use of multiple Notches : Multiple notches decreases sudden area changes.

2.Drilling additional holes : Stress concentration reduces to less changes in cross section.

3.Removal of material (Minimisation of material) : Avoids cross sections with bends to decrease stress lines density.

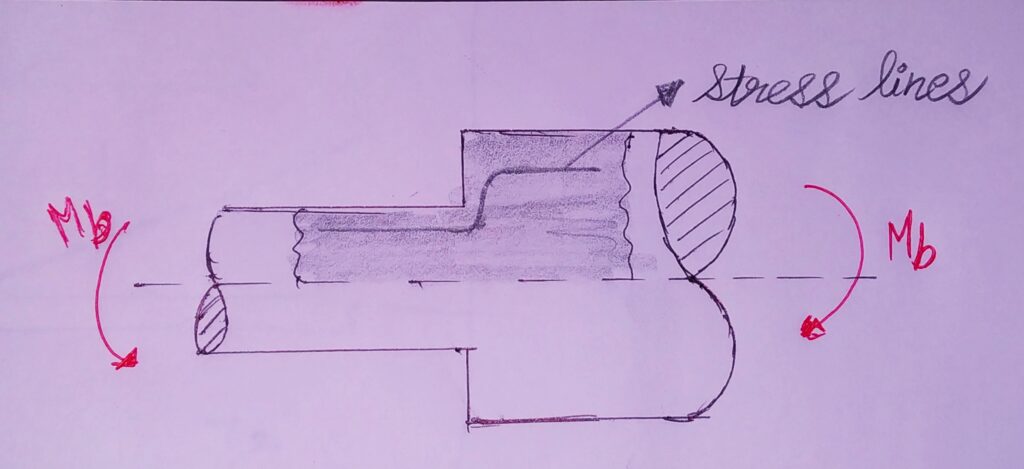

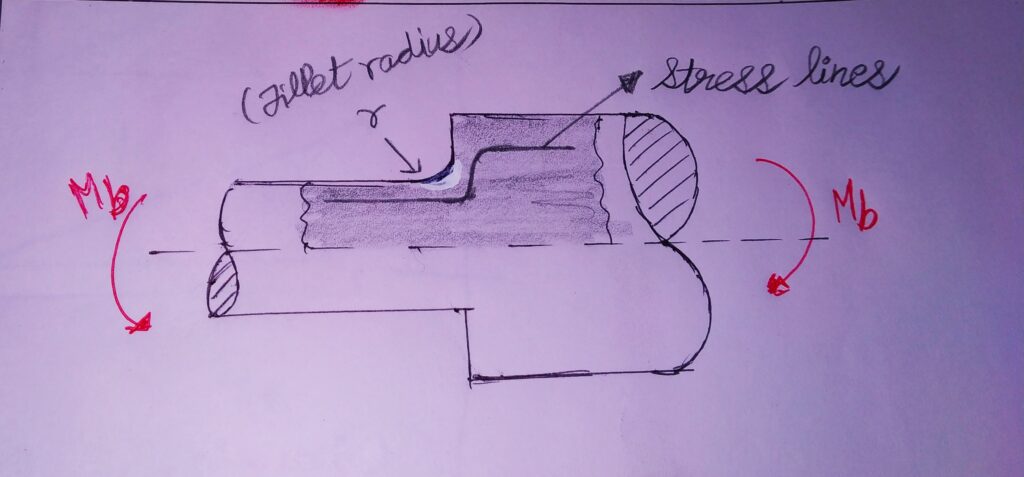

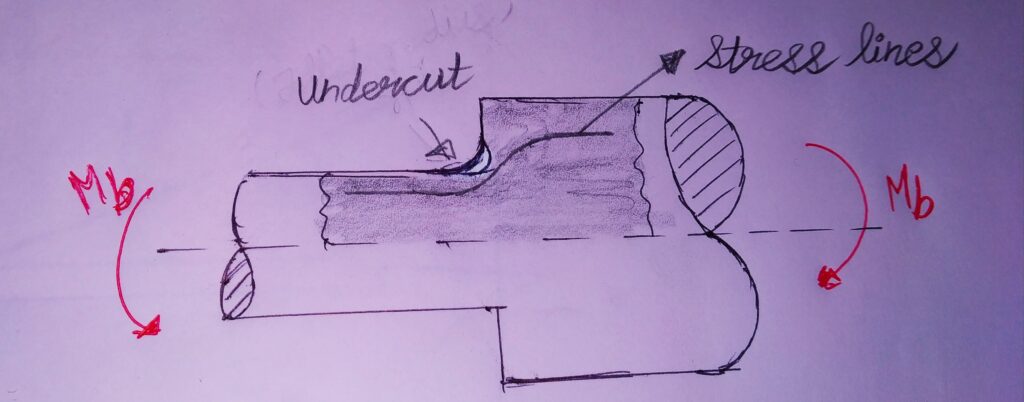

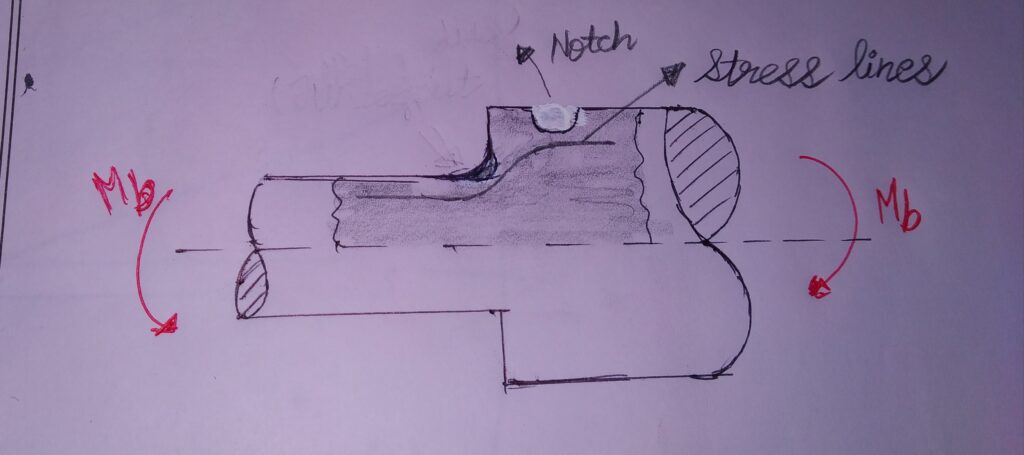

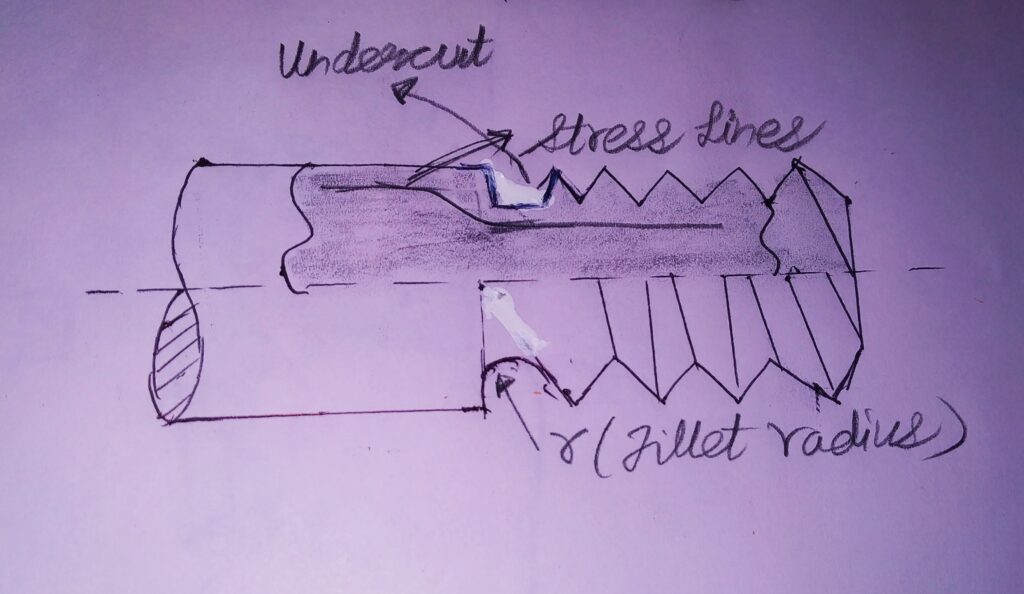

B)Fillet radius, undercutting and notch in bending members :

A circular cross section bar with a shoulder and subjected to Bending Moment taken for study.

Ball bearings, gears etc. seated against the shaft shoulder. The shoulder causes sudden cross section change due to which we see stress concentration at these sections. This problem finally was solved by reducing corners of the shoulder section through the following methods :

1.Fillet radius (r) – It should be kept as large as possible.

2. Undercutting : Undercutting provides more area at shoulder.

3.Additional Notch : Notch lessens density of stress concentration (stress lines) near the shoulder.

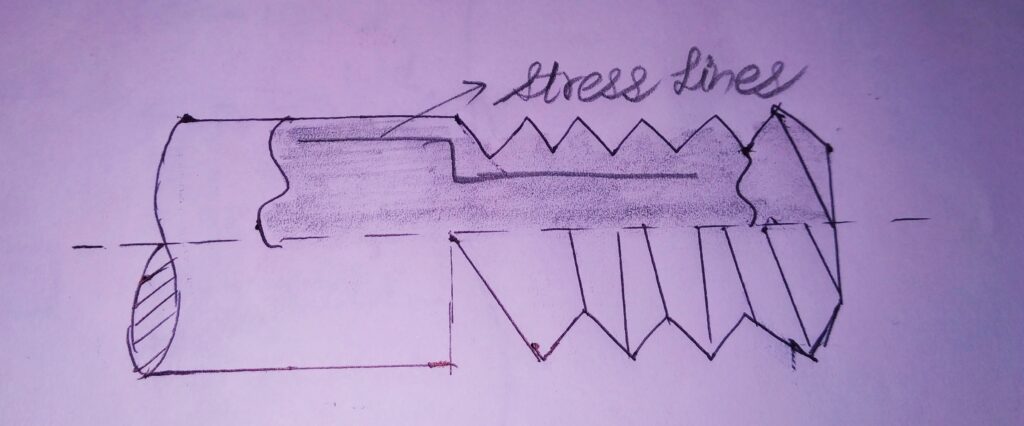

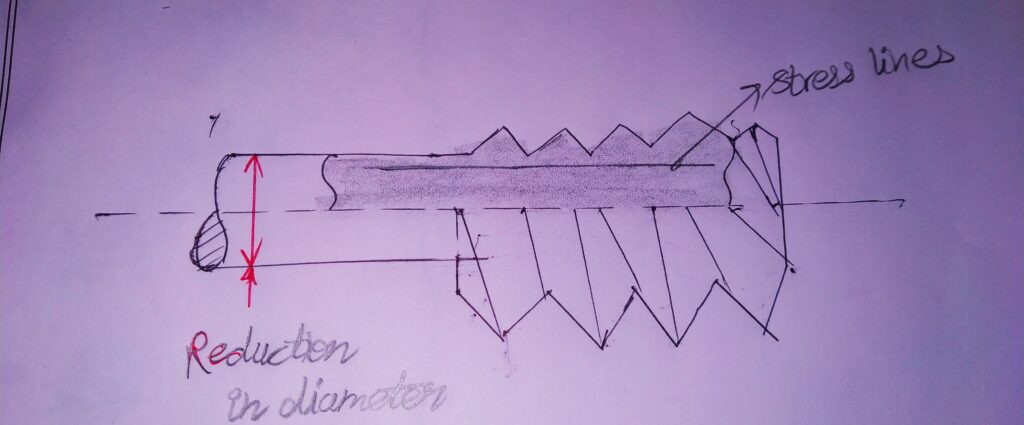

C)Stress concentration reduction in threaded members :

The stress lines seemed to bent when it passes through the threaded portion while coming from shank portion in these members.

So, an undercut made between the shank and thread portion with a required fillet radius. This helps in better reduction of stress concentration along threaded members. Following methods came for usage in this :

1.Undercut with Fillet radius : Helps in better reduction of stress concentration

2. Reduction in shank diameter: Less crowded stress lines decreases stress concentration.

These are the methods used to reduce stress concentration.

ALWAYS REMEMBER;;;;;;;;;;;;;;;

STRESS CONCENTRATION CAN ONLY PARTIALLY REDUCIBLE , BUT NOT COMPLETELY..

LETS SEE A QUESTION BASED ON THIS CONCEPT.

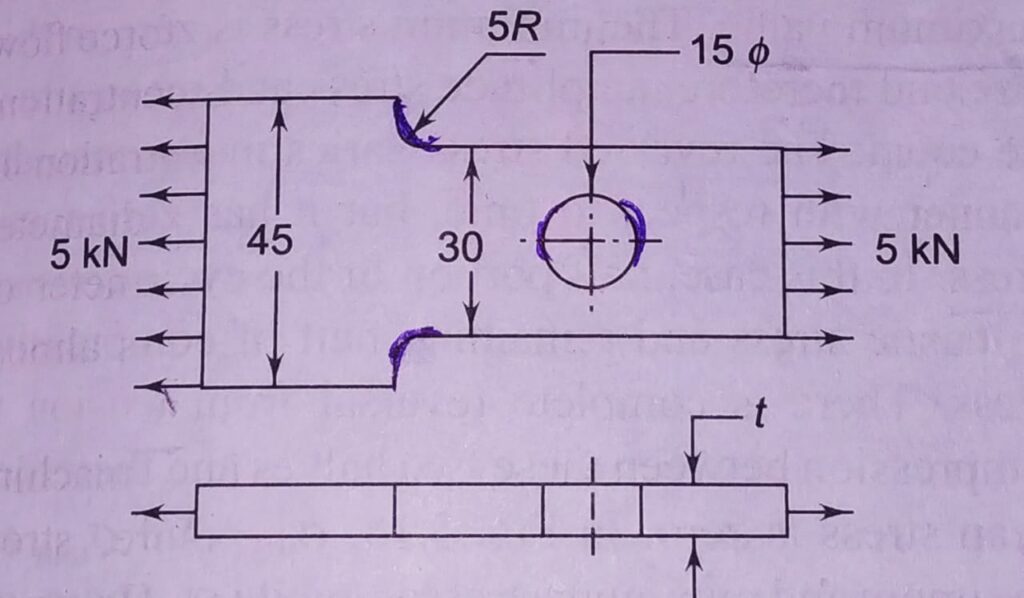

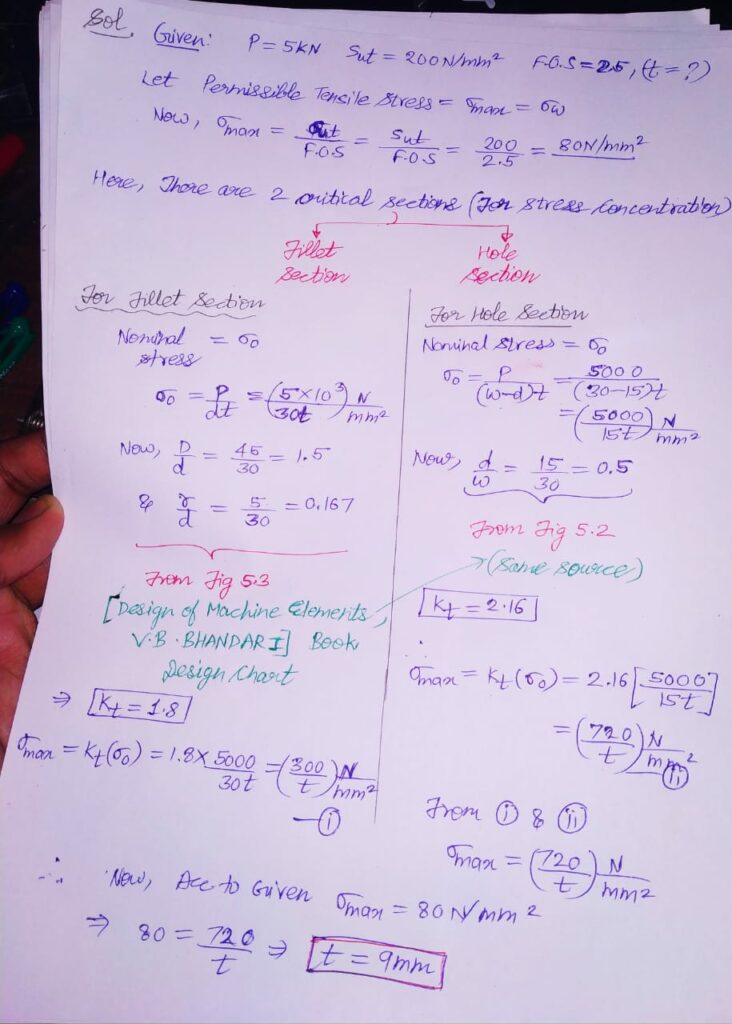

Q. A flat plate subjected to tensile force of 5 kN. Plate material is grey cast iron FG 200 and factor of safety=2.5 .Determine the thickness of plate.

SOLUTION:

ALWAYS REFER EITHER V B BHANDARI DESIGN BOOK OR DESIGN DATA BOOK OF ANY PUBLICATION FOR THE STRESS CONCENTRATION FACTOR CHARTS FOR VARIOUS COMPONENTS.